FIELD BLASTING - no dust loading in the environment

We guarantee you the best method for removing PAINT, RUST, DIRT, SCALE, MOLD, preparing the surfaces for further CORROSION PROTECTION, or creating the desired final surface structure. Blast Tehnik performs blasting at your site without extra energy sources. We also field blast steel structures.

Our qualified field teams and high-performance field equipment can handle even the largest objects.

Advantages of FIELD BLASTING

- NO DISASSEMBLY OR TRANSPORT - We provide fast and efficient surface treatment and corrosion protection at the customer's site.

- NO DUST LOAD IN THE ENVIRONMENT - we protect the worksite (including the large steel structures) and continuously extract the dust and dirt.

- A COMPLETELY SAFE PROCEDURE - We perform the blasting without damaging your machines, facilities or equipment.

- COMPREHENSIVE SERVICE - in addition to blasting services, we also apply various corrosion protection coatings: PAINTING (wet-airless, powder coating), METALLIZING (ARC) and RUBBER COATING

- PRESSURES UP TO 14 BAR - We perform the most demanding blasting operations with pressures up to 14 bar.

- WE ADHERE TO STANDARDS - we follow the requirements and protocols of our clients according to standardized procedures

Field blasting - our references:

BEST CASES OF CLEANED SURFACES

WET BLASTING - DUST-FREE BLASTING

Wet blasting is a unique blasting process for use in urban areas and other areas where loading the environment with dust is not allowed.

Only the dirt (paint, mold, rust …) is removed, while the surfaces remain completely intact. Especially suitable for: graffiti removal, cleaning cultural heritage sites …

blasting concrete

Mobile blasting is ideal for finishing walls and facades of new buildings, as well as for restoration works.

Concrete blasting is performed in predetermined stages. In this way, the customer selects the desired final structure and appearance (fine, medium, rough …). Suitable for removing:

- remains of formwork,

- traces of grinding,

- paint (facade, whitewash ...),

- graffiti,

- other dirt (limescale, mold, moss ...).

Descaling - OXIDE REMOVAL

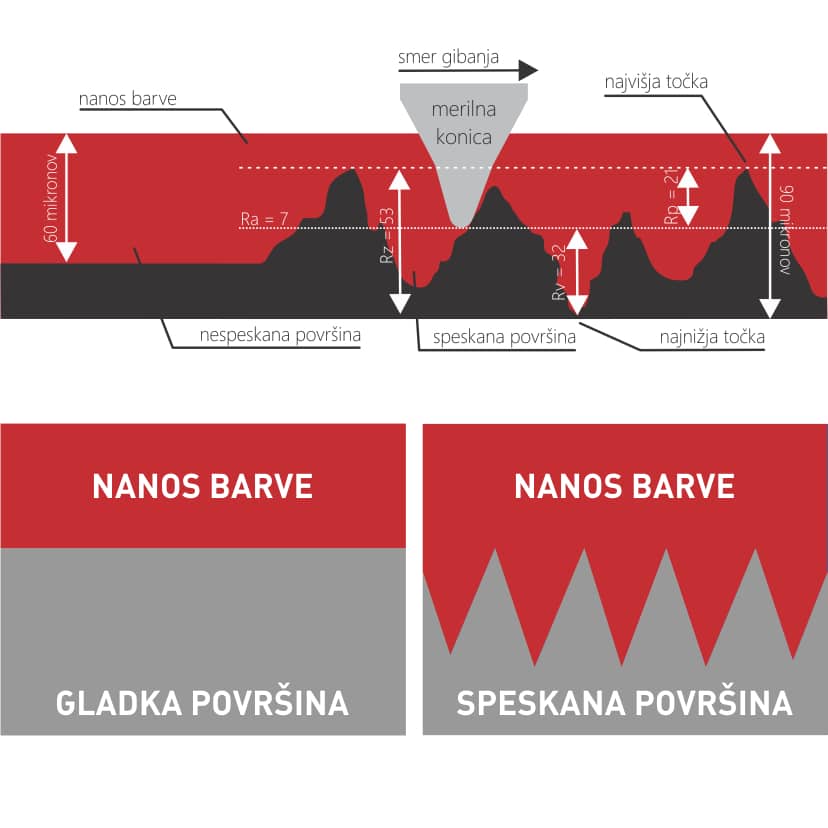

Oxide layers on steel may cause problems in machining, welding and paint adhesion. Why?

1. Air pockets are formed between the base material and the oxide layer, inside which rust is formed.

2. A hard oxide layer (400 HV) causes longer machining times and increased wear of cutting tools.

3. The welds are of poorer quality and reduced load-bearing capacity in the case of uncleaned surfaces.

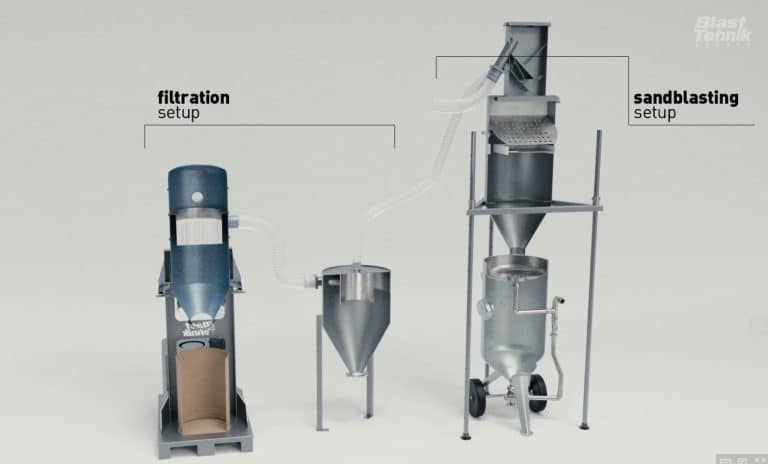

Our technology also removes extremely HARD and TOUGH coatings. In this way, we enable good weld joints and optimal adhesion of corrosion protection. We perform field blasting with a high pressure of 12 bar. With careful protection of the worksite and efficient extraction ( IBS systems by Blast Tehnik), we make sure the environment is not loaded with dust.

VESSEL BLASTING - WHY DO VESSELS NEED BLASTING?

Blasting is used to treat the surfaces of new vessels, as well as in ship restoration.

We provide high daily blasting capacities and offer dedicated blast media for various base materials – polyester, carbon, aluminium, steel …

blasting steel structures

Proper surface preparation by sandblasting extends the life of new structures and ensures high-quality restoration of existing ones.

Use cases:

- fire escapes,

- road and railway bridges and viaducts,

- blasting steel structures,

- silos,

- warehouses ...

blasting road surface markings

Due to changes in traffic regimes, safety measures or wear and tear, old road surface markings need to be removed and replaced with new ones.

Unlike the conventional methods (milling/grinding), blasting allows dust-free removal with comparable efficiency.

blasting wood

Blasting is an excellent technique for treating wood and wooden products. The process is extremely fast and efficient compared to classic sanding and brushing. After the blasting, the wood surface is suitable for immediate application of protective coatings. The blasting removes:

- paint,

- mold,

- soot,

- unpleasant odors.

pipeline blasting

Pipelines of various sizes are used to transport energy carriers such as gas, oil, etc … Most pipes are constantly exposed to corrosion, so they need the best corrosion protection and regular maintenance.

We offer our clients a premium comprehensive service with dedicated machines for automatic and manual blasting of pipe diameters 19 – 1,500 mm.

ALJAŽ TOWER - CONSERVATION BLASTING

We were a project partner in the restoration of Aljaž tower, which stands at the summit of Mount Triglav. We had to remove 18 layers of paint. The base material – galvanized sheet metal and inscriptions remained fully intact.

Use cases – conservation blasting:

- restoration of monuments

- restoration of portals and facades

- wood sculpture restoration

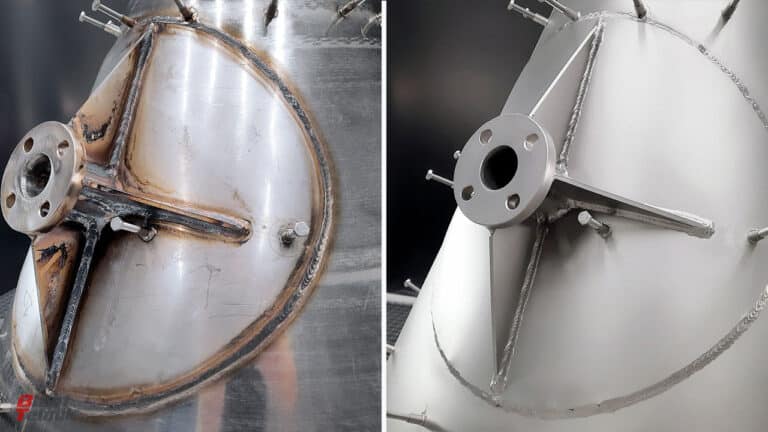

restoration of tanks

Field blasting is a solution for tanks that cannot be transported. Remove rust and other dirt – without contaminating the environment. We protect the treated surfaces by:

Use cases:

- water tanks

- pressure vessels

- water heaters

See even more examples of sandblasted surfaces in different industries.

opinions of our customers

We have been sanding a pylon all day. We realised that this was not the right approach, so we decided to try blasting the pylon. The Blast Tehnik team saved us a lot of time and worked with our other maintenance contractors to make sure that our lifts continue to operate safely.

Adi Doberšek, Marprom Mariborsko Pohorje d.o.o.

Working principle

Blasting is a process in which a blast medium is fired with high kinetic energy (under high pressure up to 14 bar) onto the surface of an object.

Depending on the base material of the workpiece, the type of protection, intended use and desired final appearance (structure), we use different BLAST MEDIA (click).

blasting quality standards ISO 8501-1

Blast Tehnik field blasting capacity

- 5 experienced field teams!

- 8 diesel and electric compressors for field blasting.

- 12 filtration and dust extraction systems - no dust in the environment!

- A wide range of machines are immediately available.

Why Blast Tehnik?

- Comprehensive service - from blasting to final surface protection (painting, rubber coating, metallizing ...)

- 5-year warranty on the provided services.

- Minimal production process downtime!

- We carry out the works according to European standards and requirements.

- We satisfy the quality requirements for even the most demanding customers, such as Groupe Renault, Novartis, Krka and others.