Painting and rubber coating

Protect your assets from the environmental factors. Improve their aesthetic appeal and increase their added value.

Our painting services are used by:

Extending the life of machines, products or facilities

Due to a relatively low cost, painting is an excellent choice for increasing the added value of machines and products. Combined with a good surface preparation such as sandblasting, we ensure excellent paint adhesion and, consequently, superior product durability.

Advantages of painting

Blast Tehnik offers professional painting technology according to European guidelines for quality coatings. Optimal and homogeneous application of paint significantly improves the final result.

- We have painting capacities for large batches and large parts (6x6x12 m).

- High resistance to scratching and impacts.

- Painting gives the products a flawless look.

- Better resistance to corrosion, heat and chemicals.

Why use our painting services?

We are specialists for surface preparation, which allows us to deliver exceptional HIGH-QUALITY and long-lasting paint coatings.

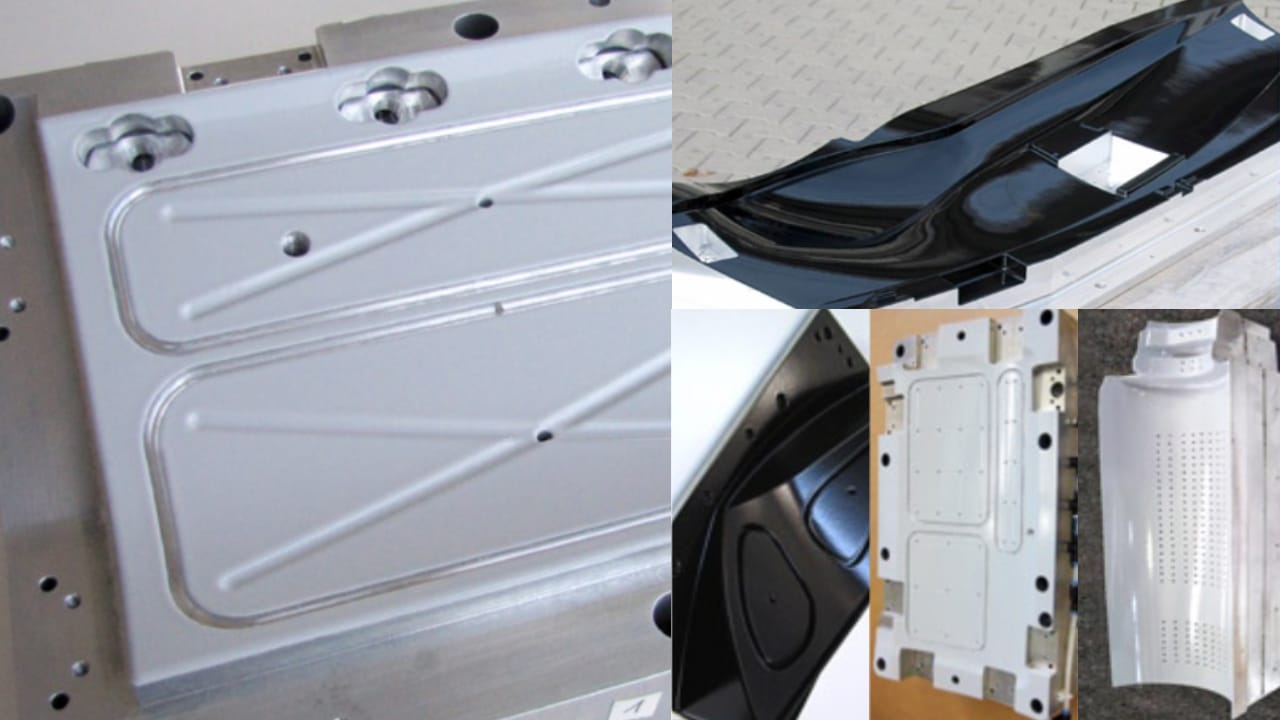

We offer both paint spraying and powder coating. and we paint everything from serial parts to one-off products.

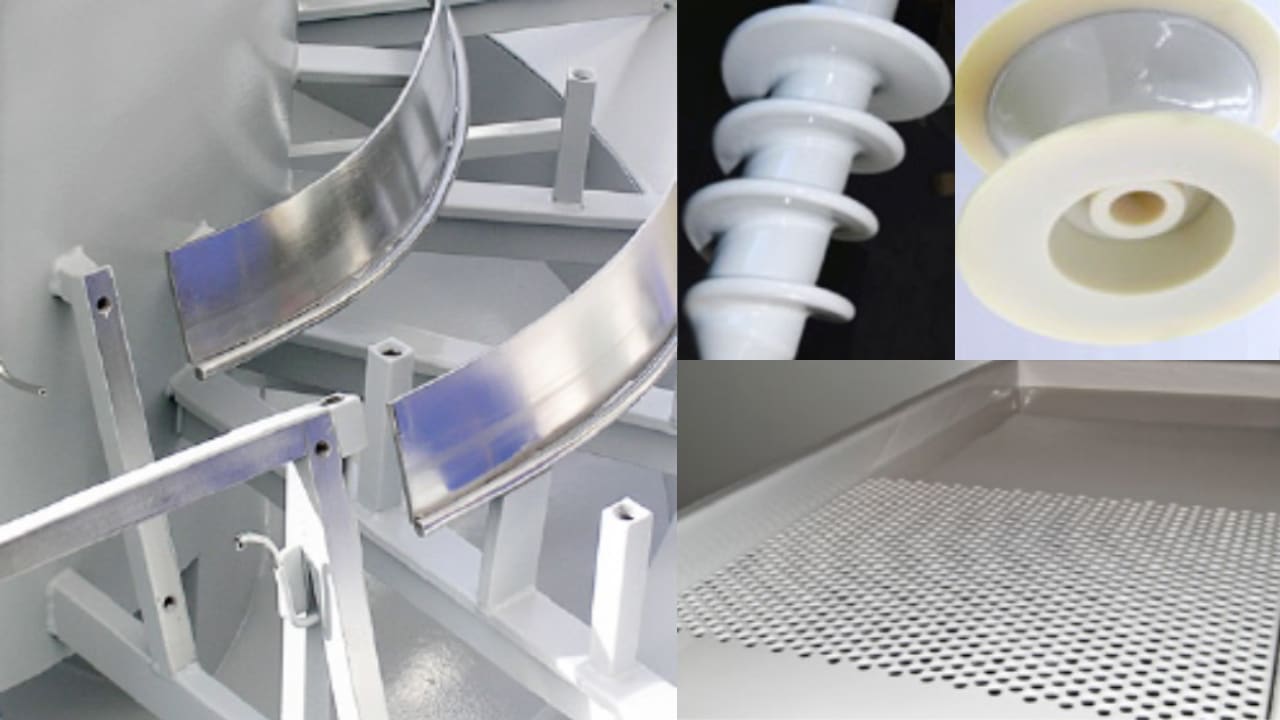

Advantages of rubber coating

Depending on the specific requirements, surfaces can be rubber-coated with different materials (anti-wear, non-slip, non-conductive …) in different color shades and hardnesses.

- There are no restrictions to the size of the workpieces.

- Processed parts are not damaged or deformed.

- We provide a comprehensive surface preparation service using the sandblasting treatment.

- Rubber coatings are suitable for a wide range of metallic and non-metallic materials.

- Possibility of multi-layer coatings for optimal protection.

Working principle

As the powder is applied with a coating gun, it adheres strongly to the surface.

The powder is then melted and evenly distributed on the surface in an oven.

Most of the powder that does not stick to the surfaces can be recycled, yielding a 98% efficiency.

Spray painting is a wet process, which allows us to apply an even and homogeneous coating.

We paint with different colors according to the RAL scale!

Depending on the customer requirements, we can use paints resistant to shocks, heat and abrasion, as well as chemically resistant paints.

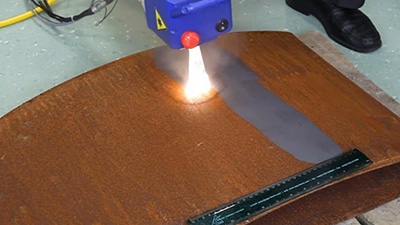

Rubber coating is a cold surface protection technique, suitable for localised or complete protection. Regardless of the size or shape of the workpieces, we provide rubber coating services in the field and at our premises.

One or more layers of elastic polymer are applied using dedicated rubber applicators and compressed air. Within a few hours, the surface is dry and the products are ready for use.

The treatment ensures a permanent and temperature-resistant protection (up to 120 °C) on almost all metallic and non-metallic materials. Our treatments comply with the FDA regulations for contact with medications and food.

Painting use cases by industry

Click one of the industries below for the use cases.

Painting for the chemical industry

Use cases:

- pipeline restoration for energy carriers and raw materials

- tank and pressure vessel restoration

- structures and technical platforms

Painting for the pharmaceutical industry

Use cases:

- fire escapes and structures

- restoration of production lines and machinery (tablet presses, mixers, drying chambers)

- restoration of tanks for sprinkler systems and technical gases

Painting for the automotive industry

Use cases:

- restoration of trailers and chassis for the commercial vehicles

- restoration of parts

- general restoration of production line units

- restoration of tanks for raw materials and energy carriers

Rubber coating use cases by industry

Click one of the industries below for the use cases.

Rubber coating in the automotive industry

Use cases:

- manipulators and grippers (protection of parts against scratches and damage)

- feeders and hoppers

- transport rollers and pulleys

Rubber coating in the pharmaceutical industry

Use cases:

- hoppers and vibrating feeders

- transport systems (rollers, pulleys, grippers …)

- weighing equipment

- anti-slip floor treatment

- electrically insulating coatings

Rubber coating in the chemical industry

Use cases:

- wear and corrosion protection on the inside of pipes transporting aggressive media

- “non stick” treatment of extruders and rollers (preventing sticking/adhesion of raw materials)

- protection of pump casings and rotors

5 year warranty

- We ensure full process repeatability.

- Coating thickness control according to EN ISO 2808.

- Pull off tests for adhesion in accordance with ISO 4624.

- Professional surface preparation by sandblasting, "COARSE (G)" to ISO 8503-1.

Official distributor for Riley

The largest marketplace for used and refurbished surface treatment equipment in the world!

Blast Tehnik d.o.o. is the official representative of Riley in the Southeastern Europe. We guarantee you the best price, warranty, service support and spare parts for all equipment in our offer!

Low price compared to new equipment.

Spare parts and maintenance guaranteed.

Warranty on all

equipment!