Dry ice cleaning machines

Ensure better quality and aesthetic appeal for your products with less production waste and downtime.

Blast Tehnik dry ice cleaning machines ensure impeccable cleaning of your equipment without damage or having to disassemble the machines.

Satisfied users:

Performance and durability for the most stubborn dirt

We are the pioneers of dry ice blasting technology, offering you both state-of-the-art technology and top quality as well as reliable and fast service support.

How do dry ice cleaning machines work?

Dry ice machines use compressed air to accelerate carbon dioxide pellets to supersonic speeds. As these pellets or particles strike the surface, they sublime away and remove dirt and contaminants. The surface thus remains dry and becomes impeccably clean without secondary waste.

Advantages of our machines

If you want to make a good dry ice cleaning machine, you have to use it yourself. This is exactly what we have been doing at Blast Tehnik since 2004, so we are capable of manufacturing the most ergonomic and technically sophisticated machines.

- Designed for the most demanding environments.

- For intensive use without downtime.

- Designed and manufactured with user comfort in mind.

- Low operating costs and high-efficiency cleaning.

The ultimate dry ice cleaning machine

PRIDOBITE VPOGLED V CENE NAPRAV

Izpolnite kontaktni obrazec in prejmite cenik direktno na vaš Email naslov.

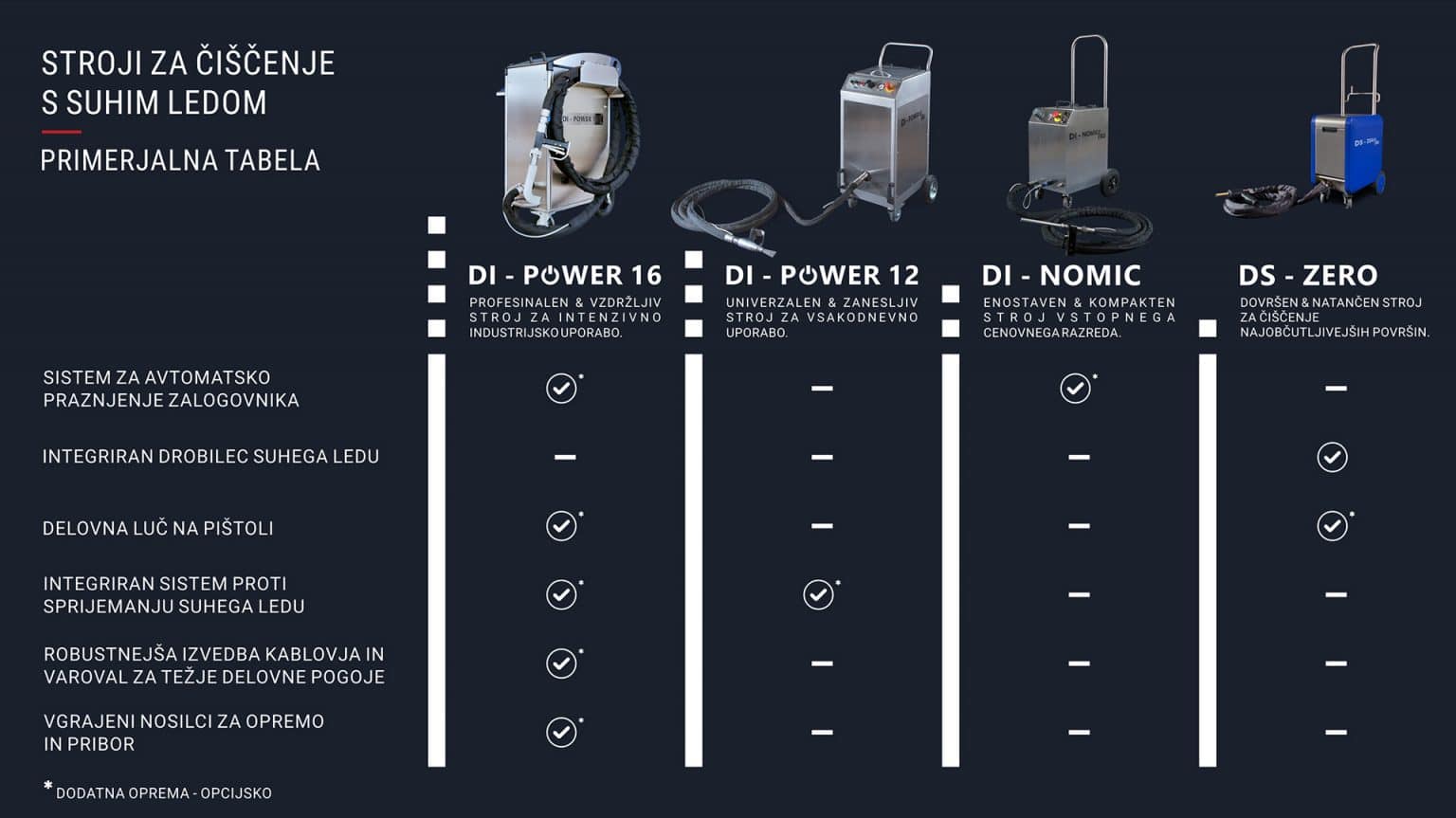

DI - POWER 16

DI-POWER 16 is a high-performance and durable machine, designed to clean even the most stubborn dirt. We have developed it in close collaboration with our customers. It is only 400 mm wide, which makes for easy relocation between the machines in your workshop.

A large (25 kg) dry ice storage box allows more than 30 minutes of continuous cleaning, while the machine impresses its users with straight-forward operation and long service life.

- built-in FESTO components and 1″ air ducting

- dry ice cleaning machines enable automatic discharging of the storage box, making it possible to remove and reuse any unused material

- robust and waterproof LED light for better visibility and overview of the cleaning area

- a wide range of accessories for optimal fulfilment of user requirements (rotary and angled nozzles, dry ice crusher, nozzles of various lengths and diameters)

- heavy duty (HD) upgrade available (suitcase for the accessories, operating hour counter, stronger cables and additional guards, holders for the blast pipe and power cable (for heavy-duty workplaces in foundries, plastics industry, rubber industry)

Download the DI POWER 16 brochure

Powerful and reliable dry ice cleaning machines, easy to operate and maintain.

Its robust housing is made entirely of stainless steel, making it ideal for demanding work environments.

- wide range of accessories – available individually or in sets (nozzles, adapters …)

- a large and insulated storage box allows for less frequent filling and excellent dry ice utilization

- adjustable ice metering

- suitable for pellets ranging in size from 1.7 to 3 mm

- machine maintenance is easy and affordable (a small number of wearing parts)

- a light and ergonomic gun with a safety mechanism

- a wide range of accessories for optimal fulfilment of user requirements

Download the DI POWER 12 brochure

DI - POWER 12

Di - nomic

DI-NOMIC is the right choice for companies that want to use the advantages of dry ice cleaning on smaller surfaces, units of equipment and components, without having to use large amounts of air and thus powerful and cost-intensive compressors.

DI-NOMIC is an ideal dry ice cleaning machine for smaller production systems, or for occasional cleaning of dirty parts and units of equipment.

- suitable for cleaning small and medium-sized objects

- ideal for daily maintenance work on process equipment and electronics

- user-friendly handling (light and handy blast hose, ergonomically designed gun grip with a safety mechanism)

Extremely precise dry ice cleaning machine for safe and efficient cleaning of even the most sensitive surfaces (sensors, circuits, installations …).

Its benefits include low consumption of air and dry ice, as well as low noise level.

Its design is complemented by a wide range of accessories to further improve the user experience.

- built-in sophisticated dry ice crushing system (0.2 – 3 mm size range adjustable for the desired cleaning intensity)

- homogeneous and continuous dosing of material

- the machine never freezes (technical design prevents the adhesion of material in the storage box)

- wide range of applications and excellent mobility

- accurate dosing and low material consumption

Working pressure: 0.1-10 bar

Ds - zero

What do our customers say?

Our maintenance crew discovered that it was necessary to clean our injection moulding tools. We needed an immediate solution, otherwise we would produce a lot of scrap. Then the guys from Blast Tehnik visited us. They brought with them various dry ice cleaning machines and delivered a presentation. Together we chose the right machine and we could start cleaning the very same day. Quite simply, without big investments or lengthy decision-making. The main thing is that it enabled us to reach 100% good products.

Gregor Vrhovnik

Head of service

Unitplast

Thanks to Blast Tehnik, we achieved an immediate result and saved a lot of time and money. Our injection moulding machines and tools are now always impeccably clean. This allows us a constant quality of products and much easier mould maintenance.

Simon Drofenik

CEO

Kovinoplastika Deplast

Why decide for our machines?

5 YEAR WARRANTY!

Our dry ice cleaning machines are proven to be reliable and durable.

They completely remove the need for chemical and manual cleaning of industrial equipment.

We carry all wearing spare parts in stock and service is available to our customers 24/7.

Why dry ice cleaning?

When it comes to stubborn dirt, burns or sensitive electronics, dry ice cleaning is the BEST choice.

This technology does not contaminate the environment, and the production can be run immediately after the cleaning. See: DRY ICE – BEST CASES OF CLEANED SURFACES (click).