Laser cleaning

Clean your surfaces without noise, dust, toxic waster or transformations in the base material.

Our laser cleaning services are used by:

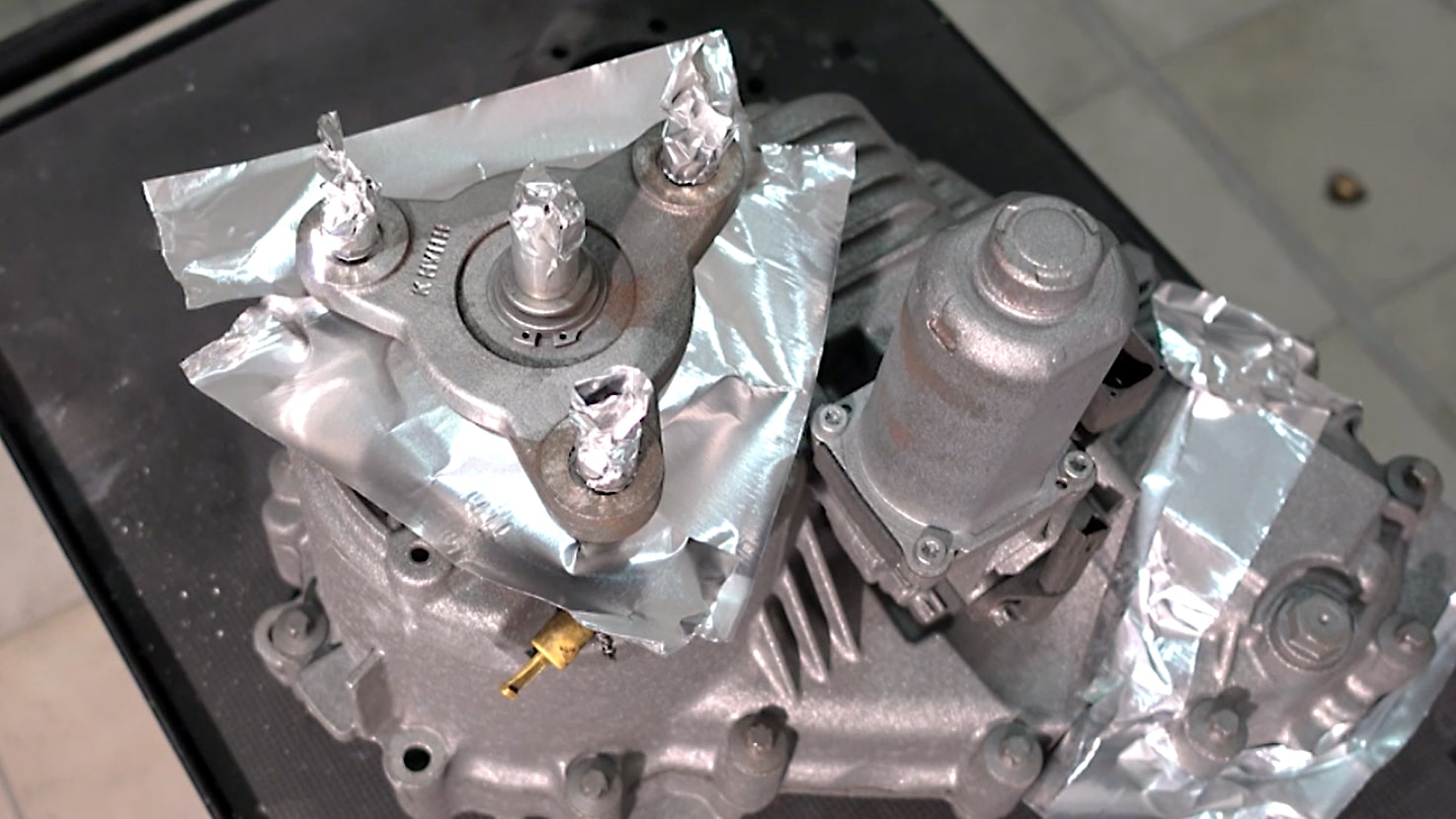

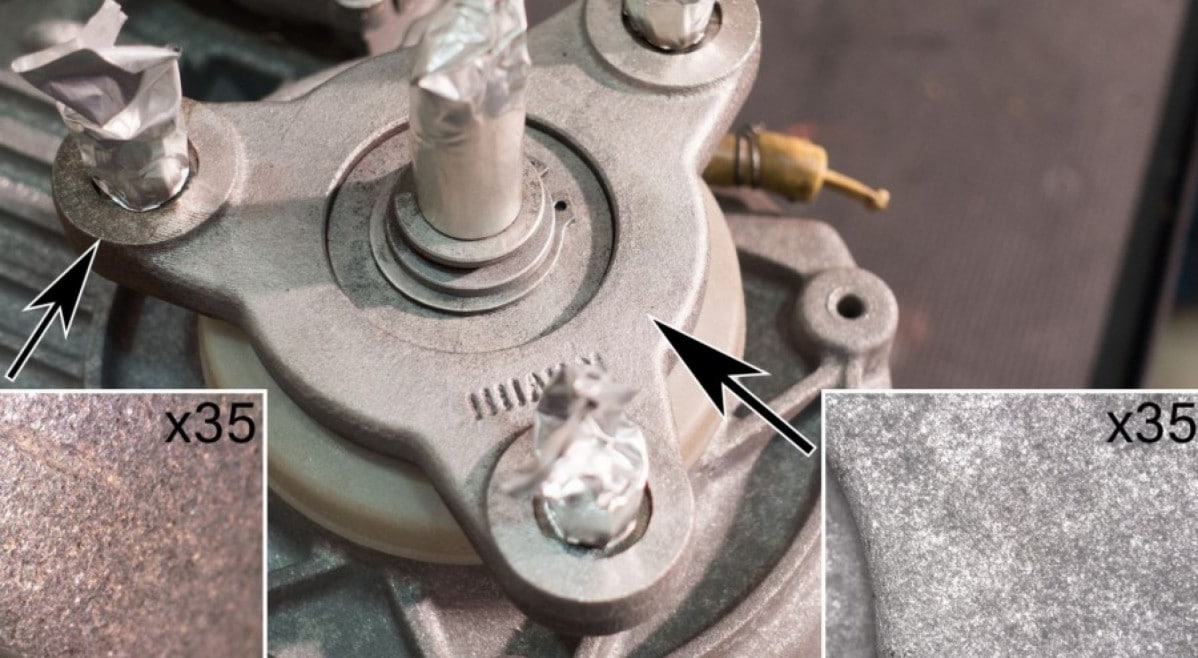

For hard-to-reach and geometrically structured surfaces

Ensure LESS DOWNTIME in your production with laser-based maintenance of machines, tools and moulds.

- Suitable for removing surface contaminants and thin layers of protective paints.

- Suitable for robotic processes.

- Suitable for activating the surfaces before the application of sealants and paint.

Why use a laser?

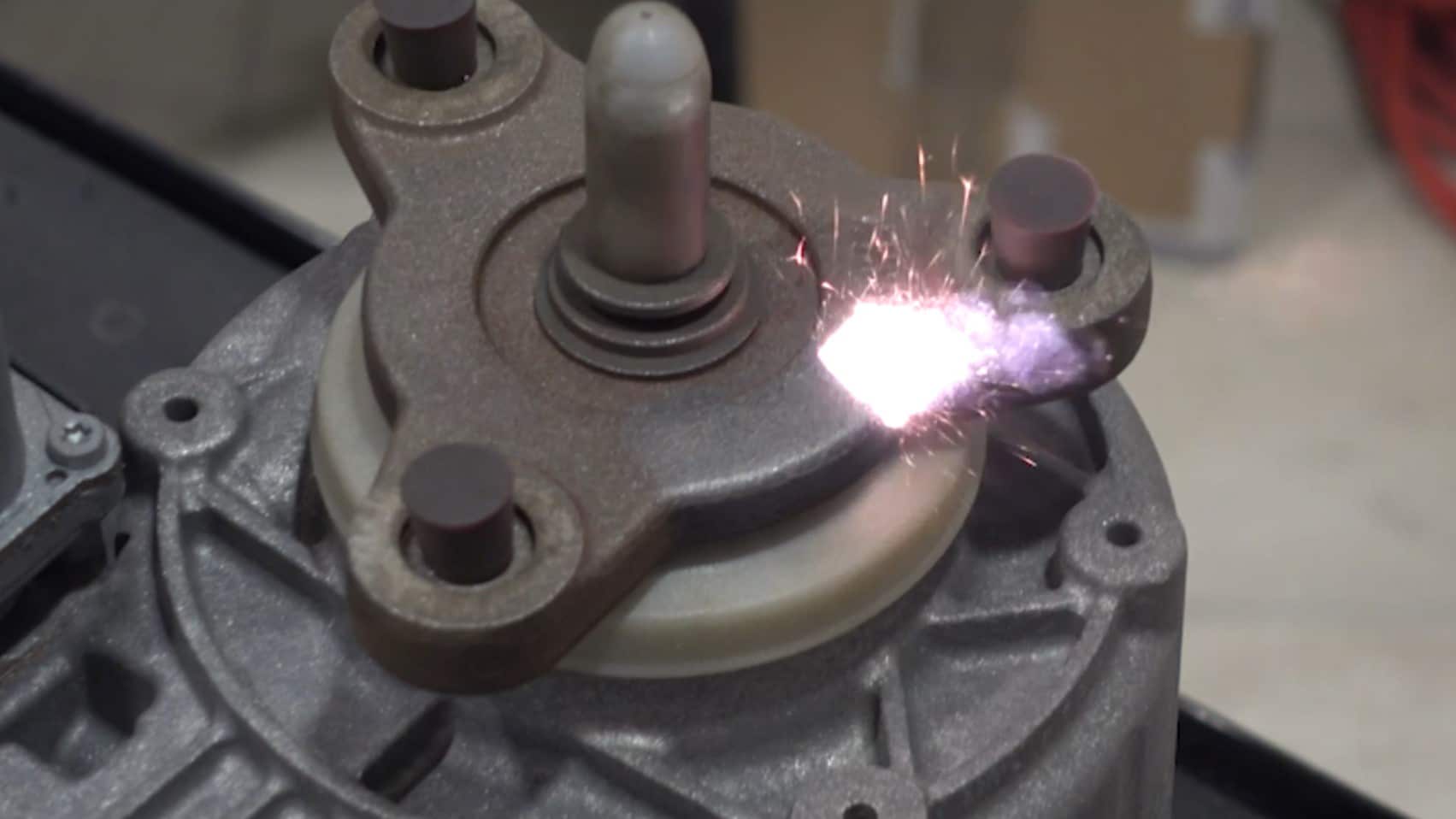

When an ACCURATE (spot), energy efficient, clean and quiet cleaning method is required, laser is the ultimate choice.

It allows easy integration in existing production processes.

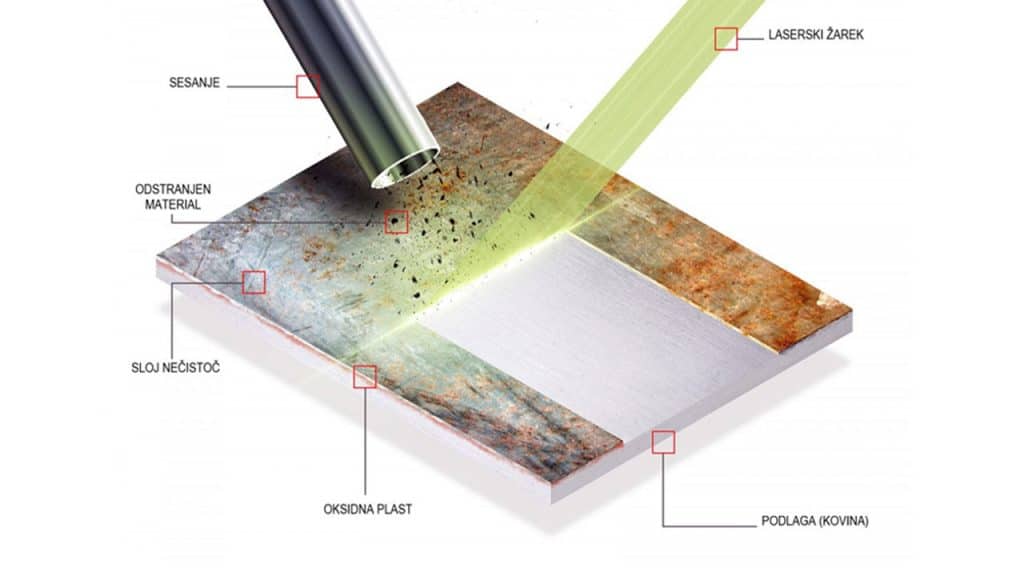

Working principle

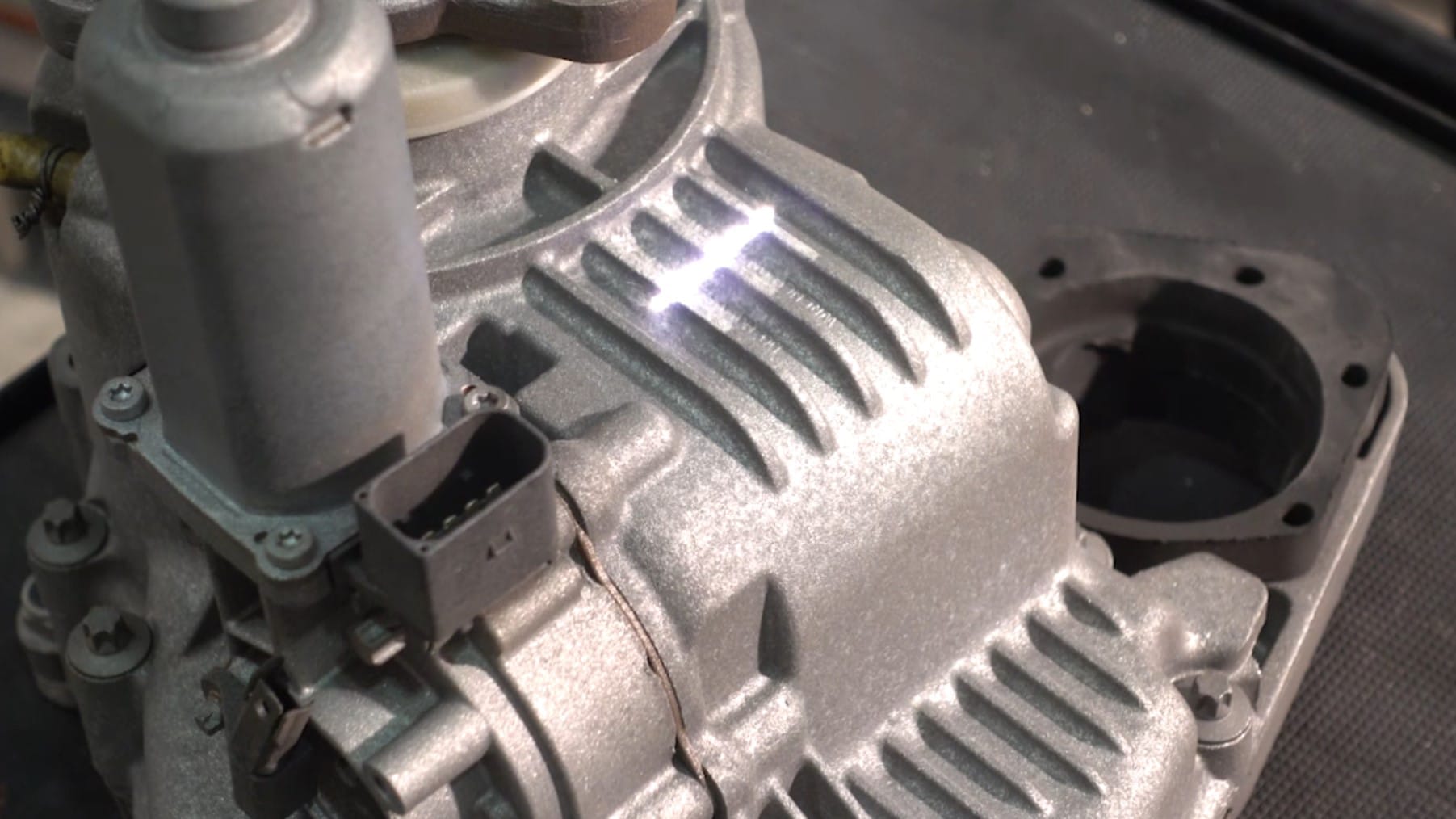

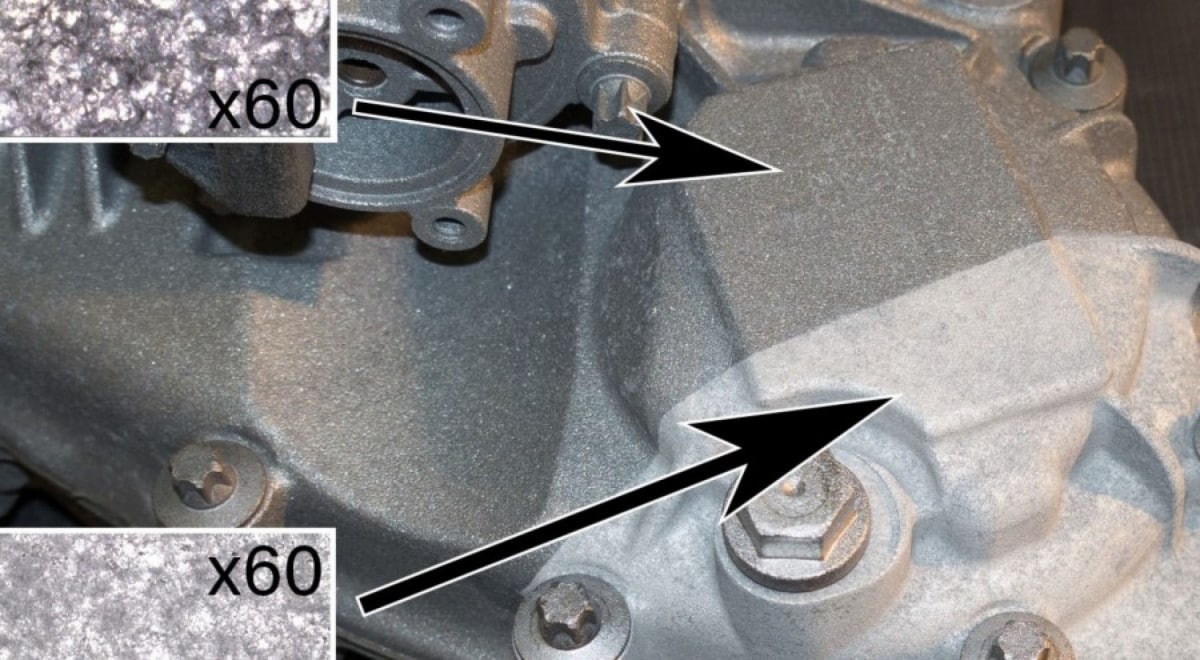

Laser cleaning uses the principle of short pulses comparable to small bullets of light, shooting at a frequency of about 200,000 pulses per second!

The laser beam induces temperatures up to approx. 3000 °C, literally evaporating the contaminants. However, the surface itself does not receive or absorb this energy and thus remains intact.

Use cases by industry

Laser cleaning – free of dust, noise and toxic waste!

Laser for the chemical industry

Use cases:

- cleaning of augers, agitators

- mould cleaning

- laser cleaning of aluminum castings

- precise paint removal on request

Why choose us?

- 5 year warranty on our services.

- Your production process does not stop.

- We carry out the work according to European standards and requirements.

Why Blast Tehnik lasers?

We know all about field work and you can be sure that our equipment is well-tested in real life conditions, because we at Blast Tehnik d.o.o. are using it every day ourselves.