Metallizing

Lower your maintenance costs, improve the functionality of the final product and provide it with 60+ years of service life even under the toughest conditions.

Our metallizing services are used by

Improve the resistance of materials to wear, corrosion and cavitation

The best protection against corrosion, wear and weather!

Advantages of metallizing

Metallizing improves the surface hardness and abrasion resistance, as well as protects the product from chemical influences.

- 6x better abrasion resistance (WC coating).

- Improved resistance of steel surfaces to chemical influences (Cr coating).

- Surface protection for the most severe corrosive environments (Zn + Al coating).

- Provides electrical conductivity to plastic materials.

- Parts are ready for further processing or installation.

Why use the metallizing treatment?

Metallizing improves the material’s resistance to corrosion, wear and weather. It improves the aesthetic appeal and the functionality of the final product.

Because it does not require drying or curing, it significantly increases and facilitates productivity.

In the process of metallisation, the temperature at the surface never exceeds 120-150 °C, so there is no risk of damage or deformation of steel.

Working principle

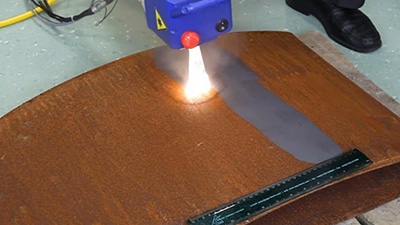

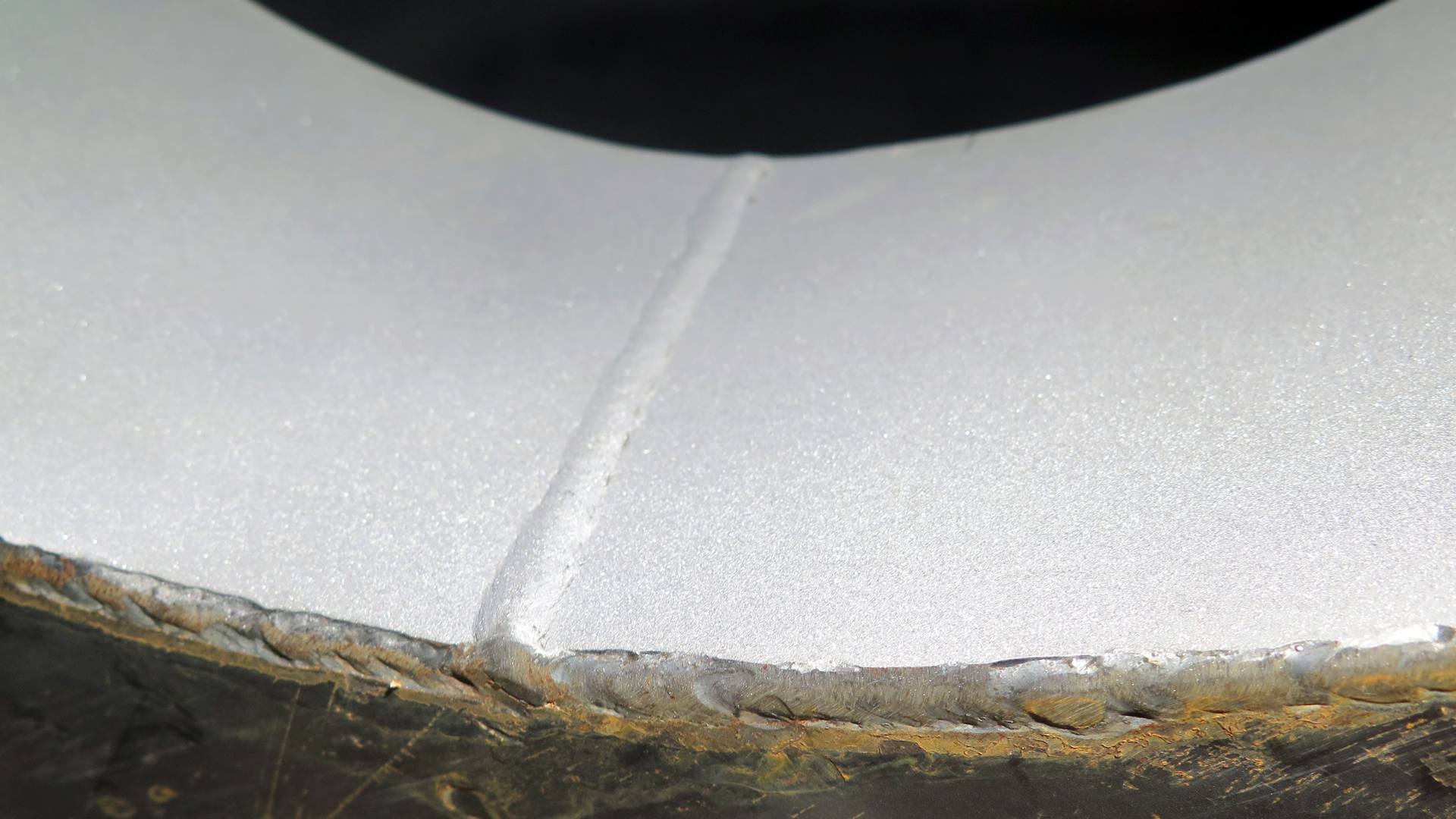

Metallizing is the process of coating the base material with a thin metal coating in the range 80 – 400 μm.

We apply the materials in various forms. Depending on the type and technological process. In the form of wire or powder.

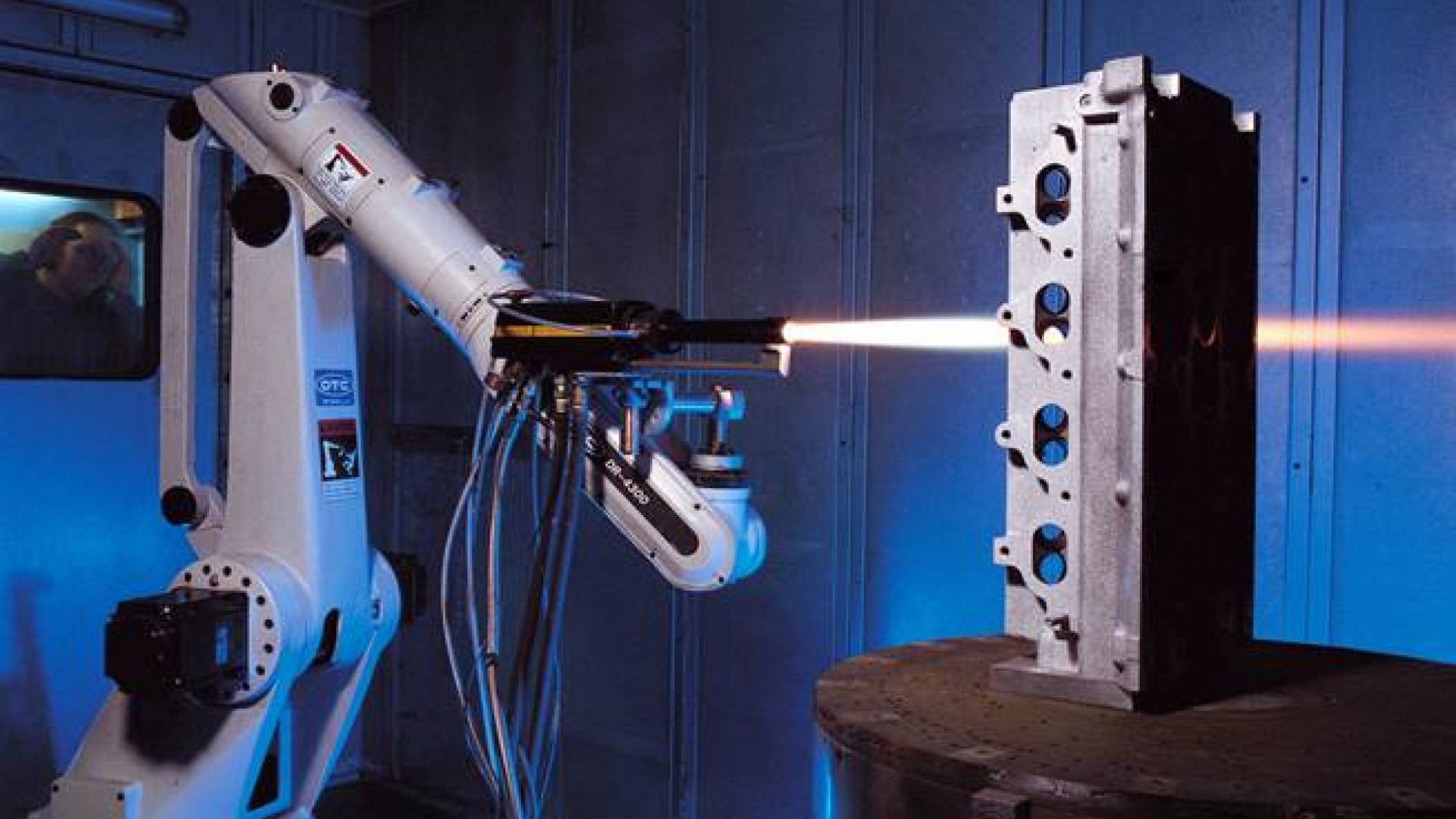

Serial robotic metallizing is performed using the ARC technology (wire arc spraying) in a dedicated spray booth, which ensures reproducible quality.

Use cases by industry

Click on one of the industries below to see the use cases of metallizing.

Metallizing in the automotive industry

Use cases:

- vehicle chassis parts used in extreme conditions

- military and mining vehicles, construction machinery, railway wagons etc.

- field repair of worn shaft supports

Metallizing for the pharmaceutical industry

Use cases:

- steel frames of pharmaceutical machines and equipment

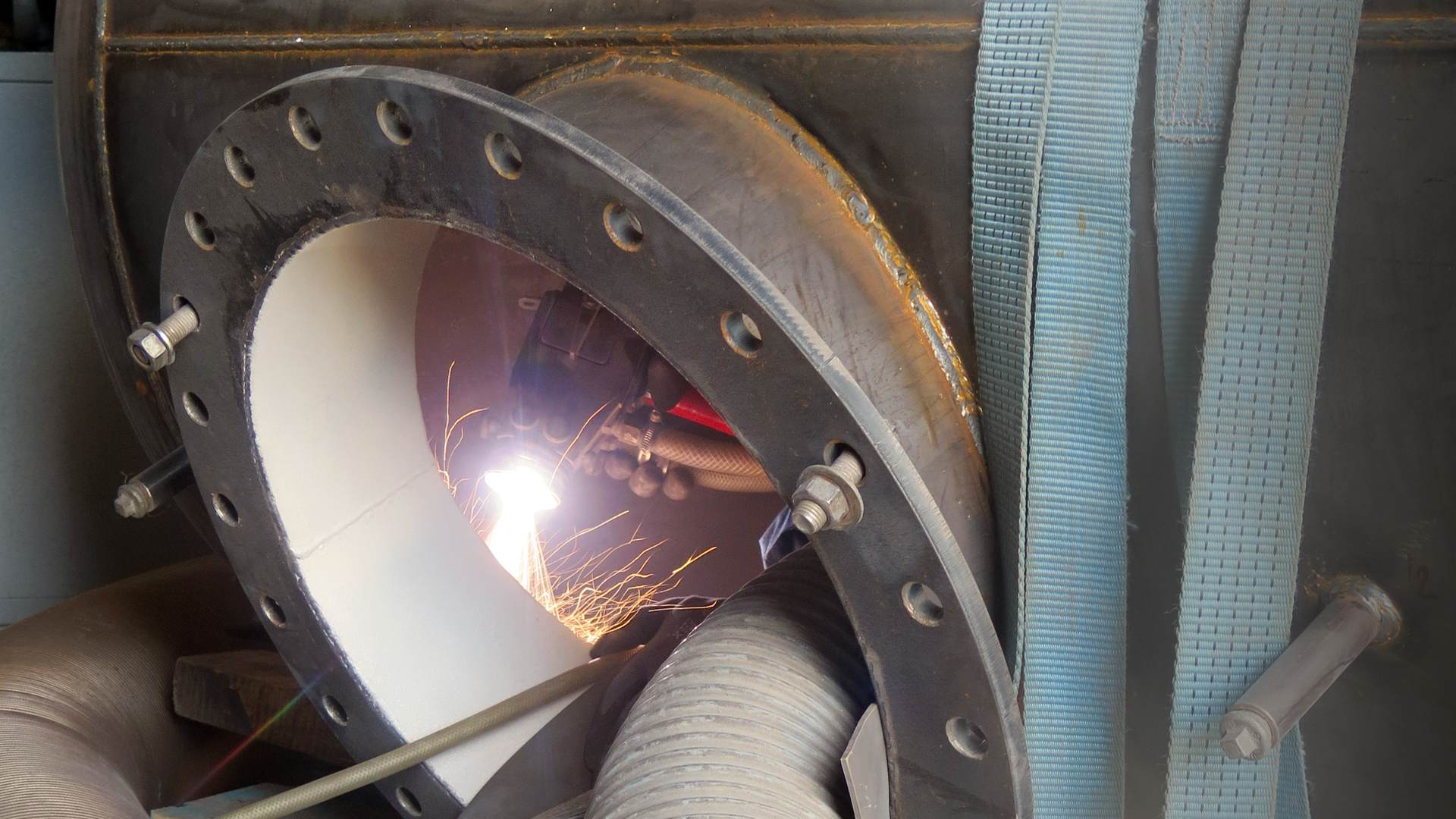

- media transport assemblies – pipelines, distributors, switches

- building structures exposed to aggressive media

- mixers for abrasive raw materials

- and other wearing parts

Metallizing for the chemical industry

Use cases:

- steel frames of machines and equipment in chemical plants

- media transport assemblies – pipelines, distributors, switches

- building structures exposed to aggressive media

- tanks and technical platforms exposed to aggressive media

- mixers for abrasive raw materials

- and other wearing parts

Metallizing for the electrical industry

Use cases:

- structural parts of wind turbines

- pipelines (protection against cavitation)

- power lines

- raw material direction nozzles

- wear parts of gates

- metallizing turbine blades (Pelton, Francis, Kaplan)

Why use our metallizing services?

- 5 year warranty on our services!

- We extend the service life of the product by 60 years!

- Robotic large batch metallizing in accordance with ISO 2063, TSM.

- Professional surface preparation with sandblasting, "COARSE (G)" to ISO 8503-1.

- Coating thickness control according to EN ISO 2808.

- In the case of tank restoration, we follow the DIN 4753 standard for drinking water storage.

- "Pull off" adhesion test in accordance with ISO 4624.

Official distributor for Riley

The largest market for used and refurbished surface treatment equipment in the world!

Blast Tehnik d.o.o. is the official representative of Riley in the Southeastern Europe. We guarantee you the best price, warranty, service support and spare parts for all equipment in our offer!

Low price compared to new equipment.

Spare parts and maintenance guaranteed.

Warranty on all

equipment!