Blasting

We perform blasting in dedicated booths, rooms, or in the field all over Europe. We blast all kinds of surfaces, materials, sizes and shapes. We have 100+ various sizes of blasting media in stock!

Our blasting services are used by:

Increase the value of your assets

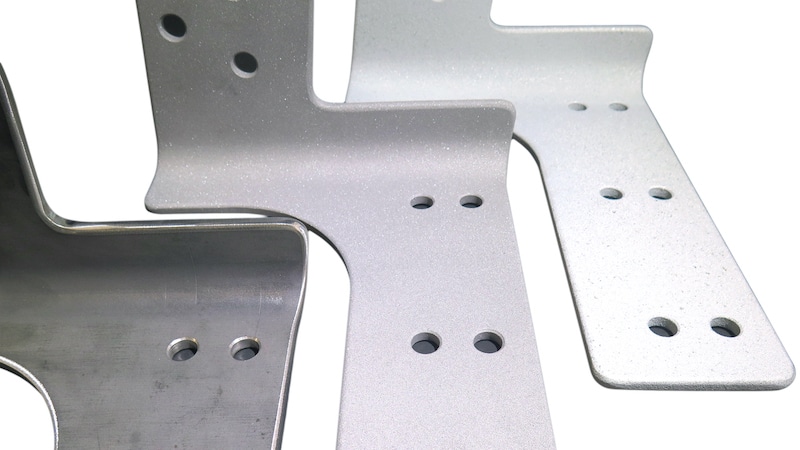

If you want to prepare a surface for the application of paint or lacquer, or to clean it, strengthen it or remove corrosion, sandblasting is the best solution! It can be used to process various materials such as metals, plastic, concrete, stone, wood, glass, etc. It can also be used to achieve various structural and decorative effects.

Advantages of blasting

The best ratio between PRICE and QUALITY compared to other techniques.

- Chemical-free process.

- A safe and harmless process.

- The blasting medium can be recycled and reused.

Why sandblast?

Blasting is used for creating rough surfaces, removing corrosion, deburring, removing paint, cleaning, fire damage restoration, creating textures according to the VOI scale and much more.

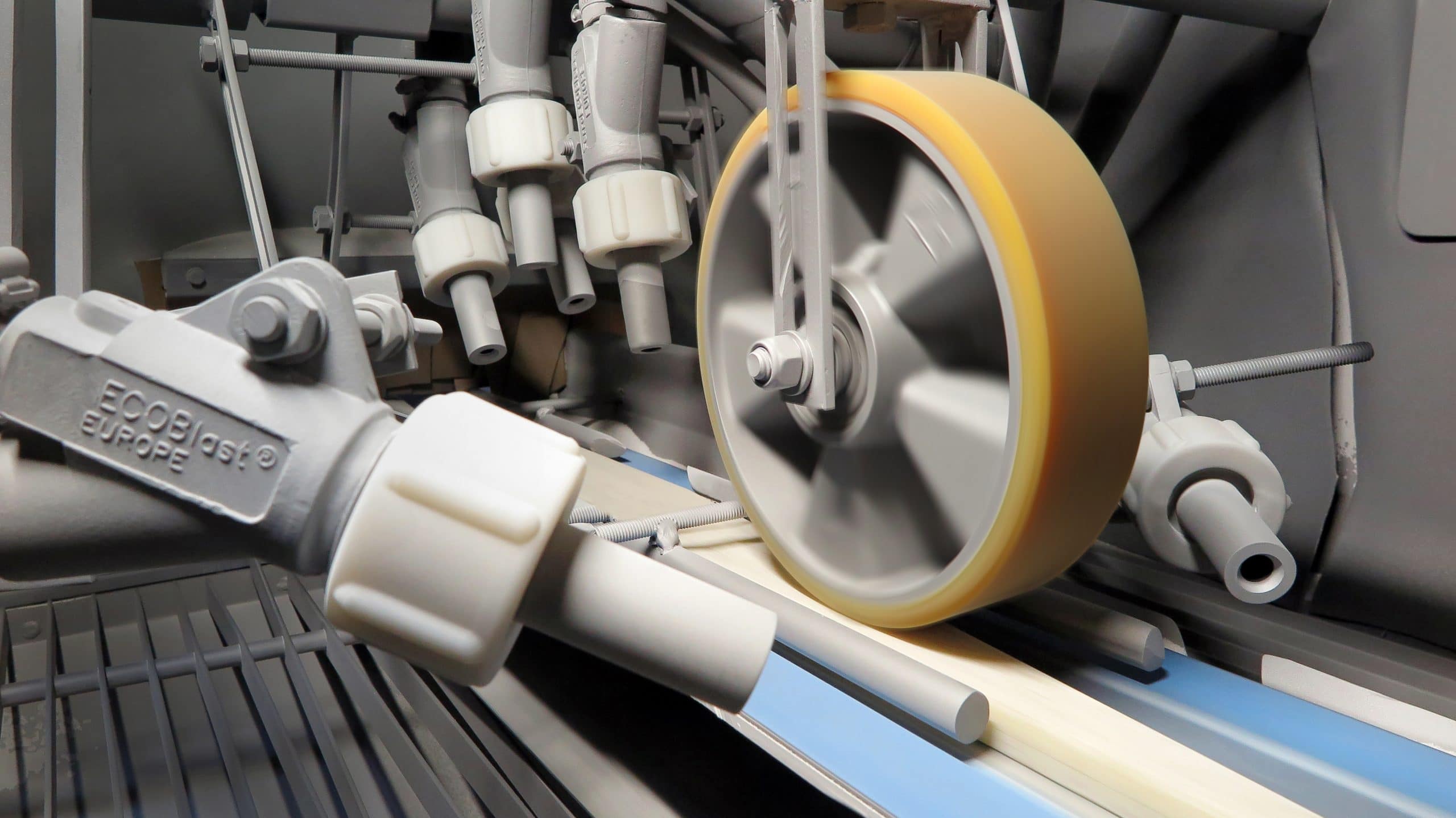

Working principle

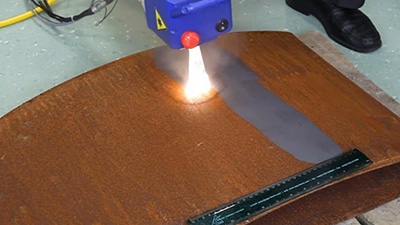

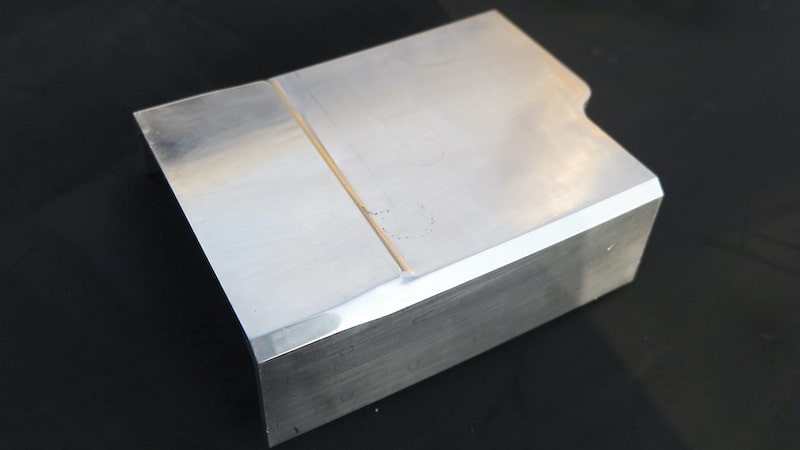

Abrasive blasting is a special technique, using compressed air for pneumatic acceleration of abrasive medium.

The medium is accelerated to high velocities (800 km/h) in a dedicated nozzle using high air pressure and used to “shell” the workpiece.

The medium strikes the surface with high kinetic energy, removing the top layer of dirt or oxides, or properly roughening it in preparation for further processing.

Use cases by industry

Click on one of the industries below to see our best blasting case studies.

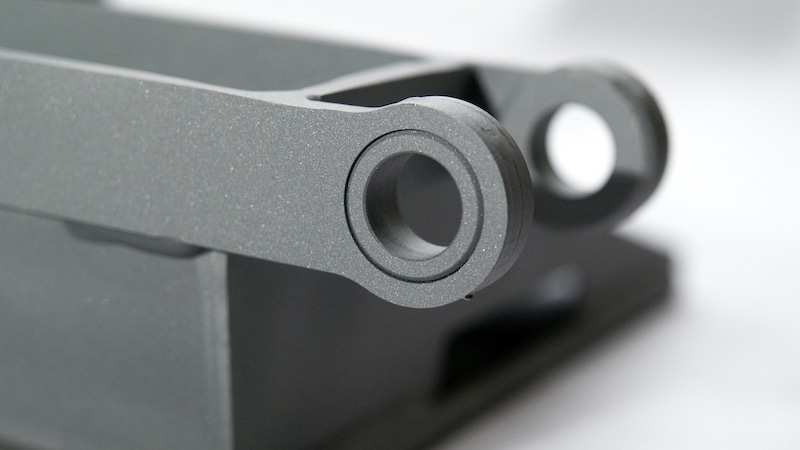

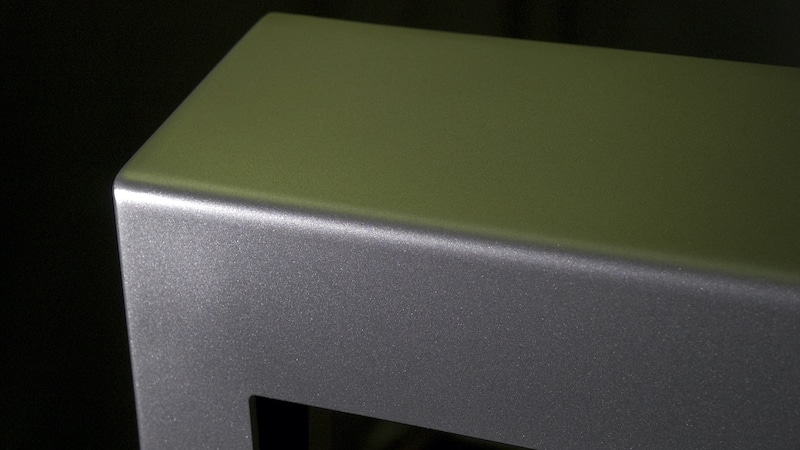

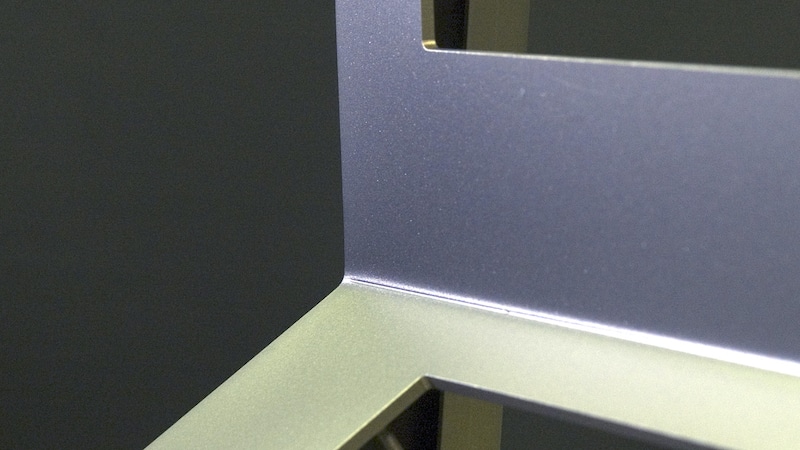

Blasting for the automotive industry

Use cases:

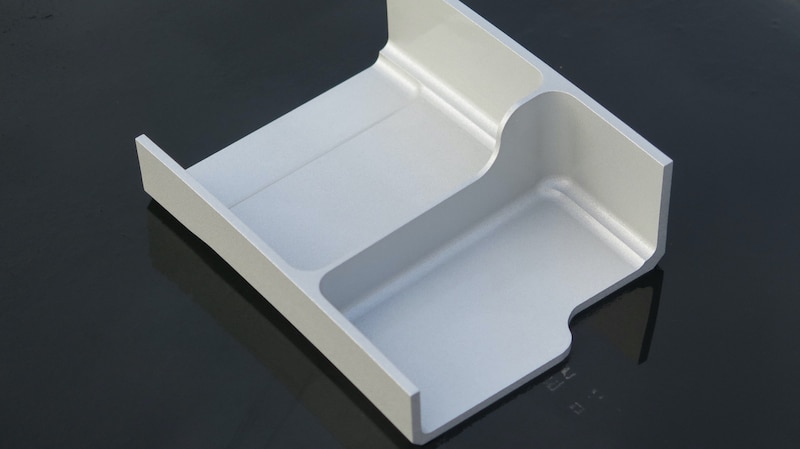

- interiors – decorative appearance of interior elements (gear levers, instrument panel and door trims, aluminium or stainless steel speaker grills)

- decorative appearance of stainless steel or titanium exhaust systems

- technical pre-processing of main and load-bearing parts of chassis subjected to permanent dynamic loads

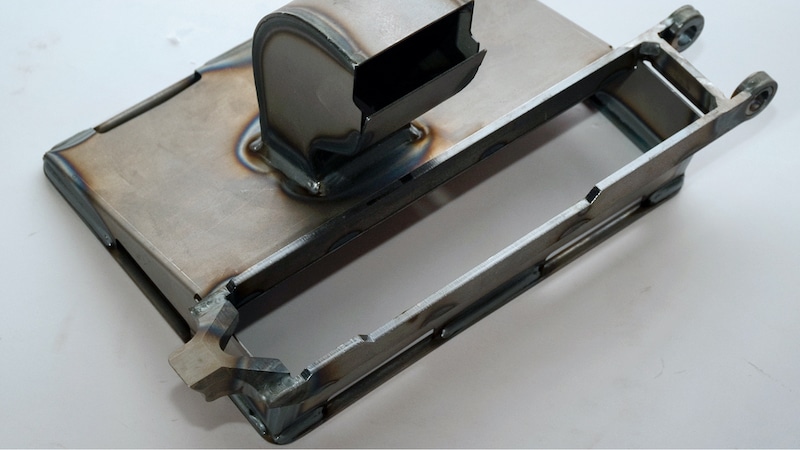

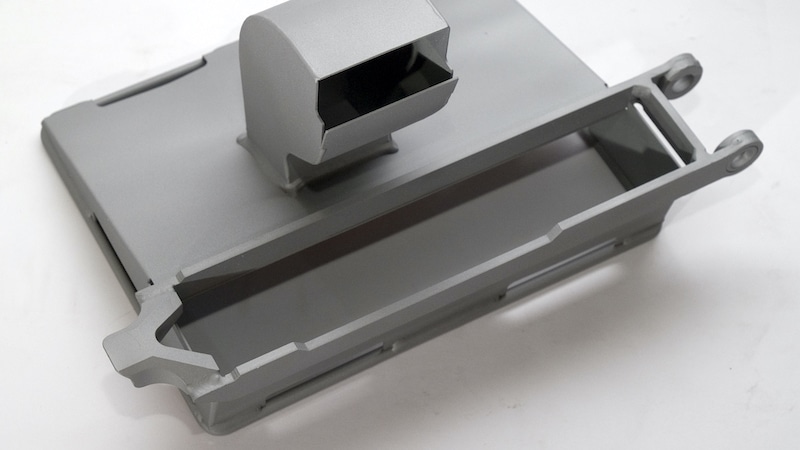

- deburring and strengthening of battery enclosures for electric vehicles

- deburring and strengthening of door safety reinforcements

- cleaning and preparation of welds for E-coating

- preparation of surfaces for bonding of composite and metal elements

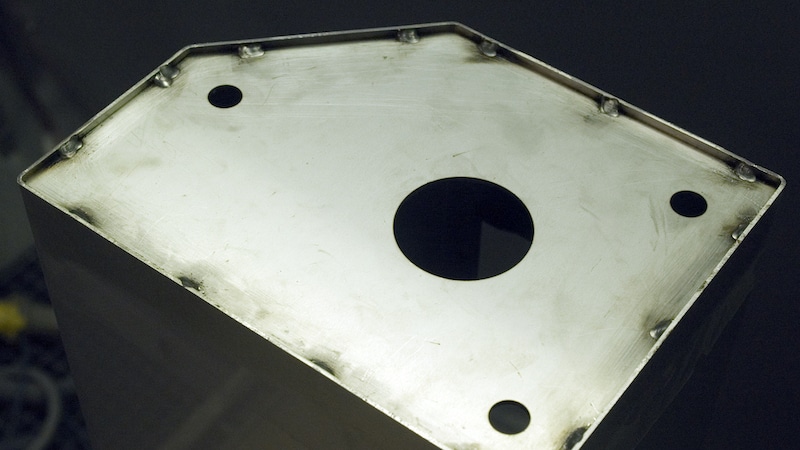

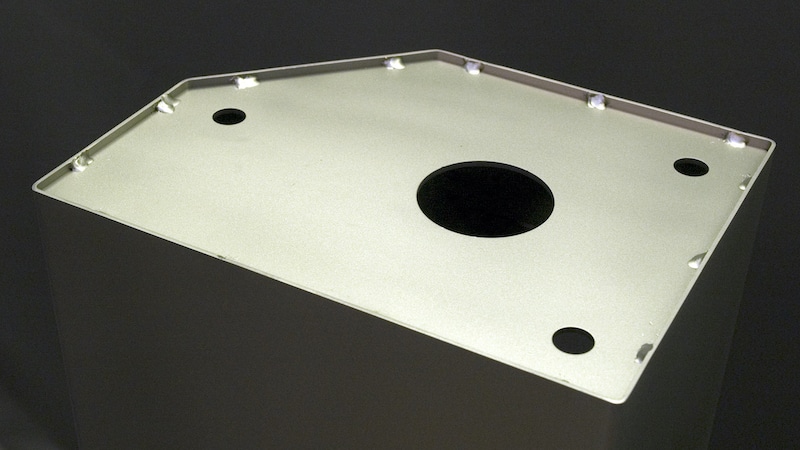

Blasting for the pharmaceutical industry

Use cases:

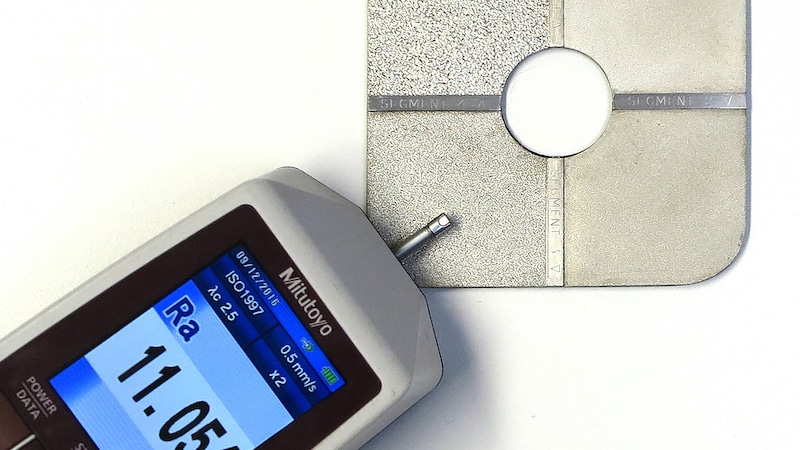

- final surface treatment of parts to the prescribed pharmaceutical industry standard (STANDARD)

- surface roughness of 0.6Ra is achievable by blasting

- process equipment, filter systems, vibrating feeders, blister plate cleaning

- platforms and other structural elements

- restoration of stainless steel mixers and tanks

Blasting in the chemical industry

Use cases:

- restoration of tanks and pressure vessels

- removal of contamination and corrosion from production equipment and machinery

- restoration of media transport pipelines

- restoration of structures and platforms

- restoration of stainless steel mixers

Blasting for the aerospace industry

Use cases:

- we use the standard (STANDARD)

- commercial aircraft rims (Boeing, Airbus, Bombardier, Safran)

- “paint stripping” – non-abrasive removal of paint from various materials (aluminum, composites, plastics, steel, fiberglass)

- “wet blasting” – blasting using a liquid without deformation of the workpiece

- cleaning of 3D-printed parts

- decorative appeal of interior elements (handles, panels, trims …)

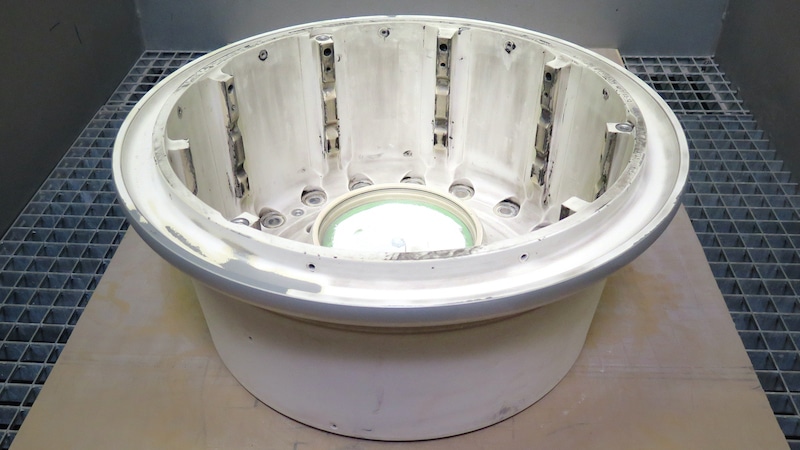

Blasting for the electrical industry

Use cases:

- restoration of water turbines (Pelton, Francis, Kaplan)

- restoration of locks and other load-bearing structures

- robotic restoration of pipeline interior (⌀ 60-1800 mm)

- restoration of power lines and transformer stations

- preparation of surfaces for bonding of composite and metal elements

- preparation of surfaces for metallizing and finishing

Our blasting services

Our blasting services are used by many international corporations and more than 70 largest Slovenian export companies.

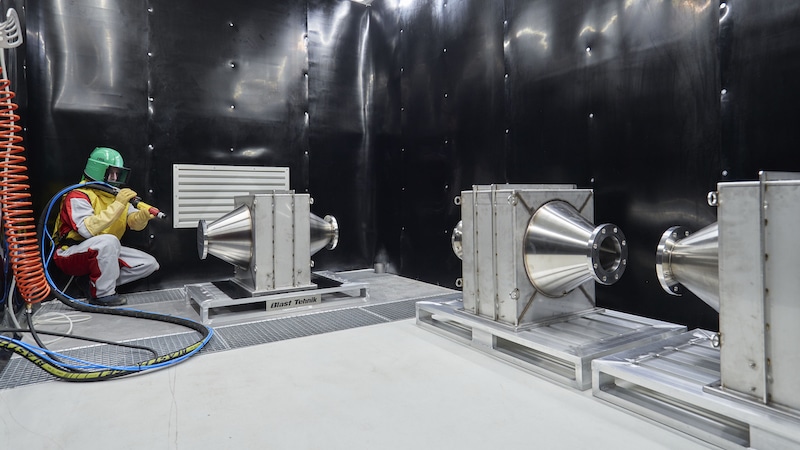

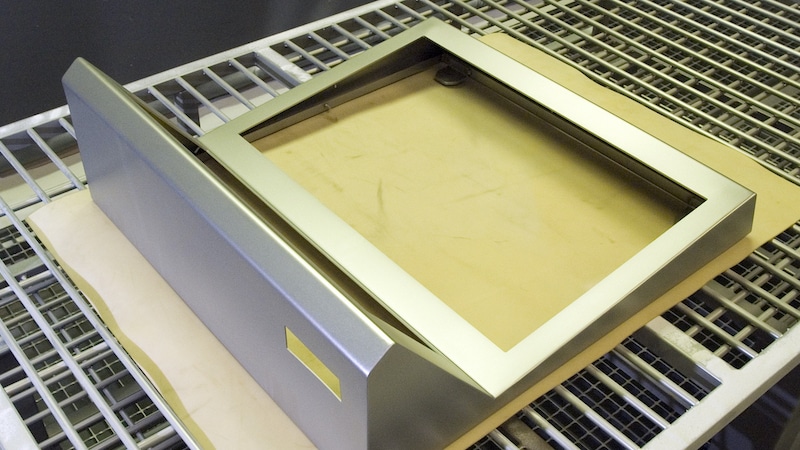

Blasting of large batches

- A completely repeatable process.

- Standardized work methods.

- Automated blast booth.

Small batch blasting

- We process all types of materials.

- We have several dedicated blasting facilities for non-stainless and stainless materials.

Field blasting

- We provide our services within a 1000 km radius.

- 5 quick-response field teams.

Customer opinions

We have been sanding a pylon all day. We realised that this was not the right approach, so we decided to try blasting the pylon! The Blast Tehnik team saved us a lot of time and worked with our other maintenance contractors to make sure that our lifts continue to operate safely.

Adi Doberšek

Deputy technical director

Marprom Mariborsko Pohorje d.o.o.

We have found a trustworthy business partner in Blast Tehnik. Courtesy of their treatment services, we are achieving excellent bonding results with composite profiles. We especially appreciate their production capacities and precise process control, helping us to maintain good relationships with our demanding end customers.

Christian Steiner

Sales

Excel Composites GmbH (Austria)

More than 30 years of experience

- Thorough incoming-outgoing control.

- Automated blasting booth and 5 field teams.

- Professional surface preparation by sandblasting, "COARSE (G)" to ISO 8503-1.

- In-house laboratory for measurement of surface properties after the treatment (roughness, coverage, adhesion, RO-TAP sieve shaker for suitable blasting medium size, protective coating thickness ...).

blast machines

Many years of experience in installing and servicing blast machines are a solid foundation for the design, development and manufacture of blasting equipment.

We produce everything from smaller blast cabinets to larger automated blast rooms for serial blasting.