The extremely fast remediation of the fairground fire

Three weeks ago, a fire broke out in one of the halls at the Celje Fairground, but the facility has already been remediated and is ready for exhibitors and visitors.

How did we clean the soot at the site of the fire in record time? 4.000m2 of surfaces in just 6 days!

We restored a fresh appearance to contaminated areas and eliminated unpleasant odors without using water.

Cleaning the Fire Site with Dry Ice/Snow

There was a fire that firefighters managed to contain quickly, preventing complete destruction of the building. The smoke, however, caused significant damage throughout the entire facility.

Soot completely covered the ceilings and walls, and it was crucial not to clean it with water or dry vacuums, as doing so would embed the soot into the concrete pores, making it nearly impossible to remove.

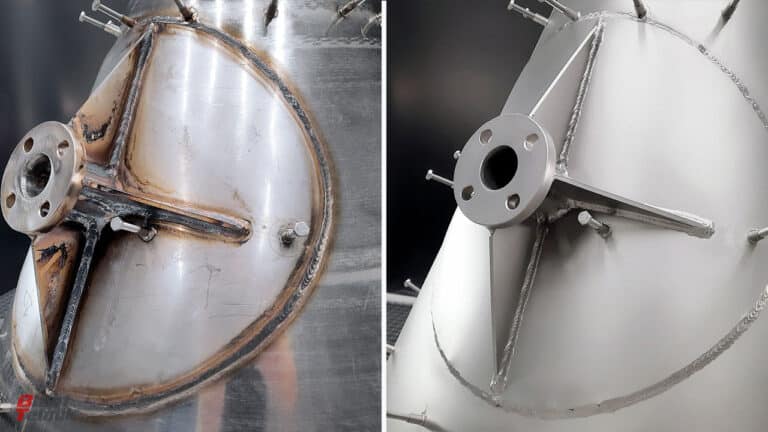

Using a special dry ice technique, we effectively removed all the soot and restored the surfaces to their original appearance while eliminating the soot odor.

THIS TECHNIQUE REQUIRES NO WATER!

Particles of dry ice are blasted onto the surface at high pressure, exceeding 1,000 km/h, and upon impact with the hard concrete substrate, they create micro-explosions (sublimation), thus peeling impurities off the surface. Sublimation occurs between the air pocket in the concrete and the soot.

The dry ice cleaning process is extremely fast. With five teams, we managed to remediate 4,000 square meters of surfaces in 6 days. The client demanded rapid cleaning because the facility needed comprehensive remediation within 16 days, in time for the International Industrial Fair where our company also exhibits.

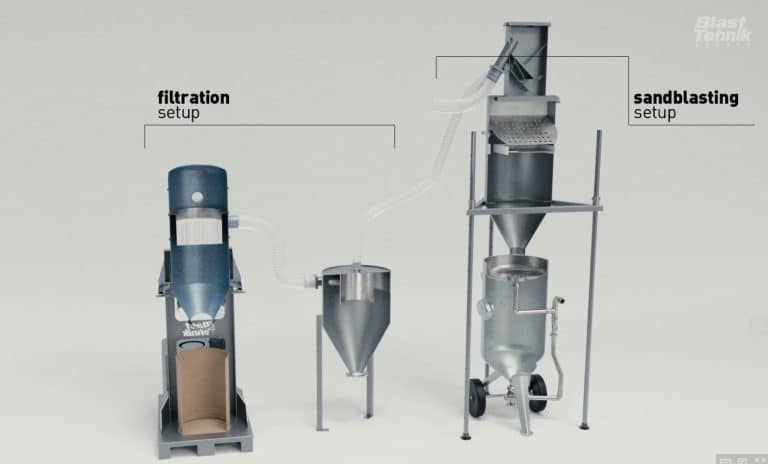

Visit us to learn more about dry ice/snow surface treatments, laser cleaning, and sandblasting.

Thanks from the Executive Director of Celje Fair

for express cleaning after a fire:

“On the night of March 23 to 24, Celje Fair was hit by a fire that destroyed the catering facility in Hall E, the Blue Hall in the congress center above Hall E, and a large part of Hall E.

The additional challenge was that we have the International Industrial Fair from April 18 to 21, which includes all our permanent exhibition halls and an additional assembly hall M.

Since it is a fair where large and heavy machinery is exhibited, preparing for this fair is an extraordinary logistical challenge. Exhibition spaces start being set up and arranged three weeks before the fair. Even Hall E, which was severely damaged by the fire, is full of exhibition spaces at this year’s fair.

We managed to negotiate with the exhibitors in this hall to allow them to prepare their exhibition spaces only 7 days before the fair begins and to work even at night. However, despite this, we had only 16 days for the remediation of this hall after the fire.

With traditional cleaning and remediation methods, considering the state of Hall E after the fire, it would have taken several months to make it usable.

Fortunately, we came into contact with Blast Tehnik d.o.o., the only company in Slovenia that carries out fire remediations with dry ice. Due to the high cost of remediation using this method, we were initially somewhat skeptical, but due to the time pressure of the upcoming fair, we accepted the offer.

Now, after the completion of the dry ice remediation, we realize that we made the right decision.

Not only is remediation using this method significantly faster, but it is also the most cost-effective. To achieve a similar result (which is nearly impossible with other methods), extensive washing and sanding of ceilings, walls, and load-bearing structures with many hard-to-reach corners and surfaces would have been necessary, followed by drying and finally five to ten layers of paint, which would have cost even more than dry ice remediation, not to mention the time and lost revenue when the hall could not be used.

In addition to the technology itself, I must commend the employees of Blast Tehnik, especially their attitude and approach. They responded immediately when we informed them of our situation and worked full days, even on Saturdays and Sundays. Their approach, both in negotiations and in the execution of the work, was extremely professional and efficient.

I want to thank them through this channel, as without them, there would be no MIS fair in Hall E this year. Instead, exhibitors and visitors to this hall will be greeted with an even more beautiful space than in previous years.”

mag. Robert Otorepec