Industrial filtration and DUST EXTRACTION for the toughest conditions!

Blast Tehnik develops and manufactures high-performance systems for dust and smoke extraction. In your production plant, they can improve the air quality, cut the operating costs and improve work safety.

Introducing our industrial dust extractors: EXTRACTOR 4/6-10.000 in the HEAVY DUTY and STANDARD versions.

ADVANTAGES:

- Our filtration systems PREVENT THE CONTAMINATION OF YOUR PRODUCTS and protect your workers from harm.

- Extraction of various media is possible: DUST AND COMBUSTIBLE DUST, OIL VAPORS, SMOKE …

- STAND-ALONE INSTALLATION or RETROFITTING to your existing extraction system.

- Suitable for many applications: WELDING, METALWORKING, WOOD PROCESSING, PAINTING AND POWDER COATING, BLASTING …

- CONTINUOUS OPERATION with the AUTOMATIC FILTER CLEANING function.

TECHNICAL DATA:

MODULAR DESIGN, 100% FLEXIBILITY

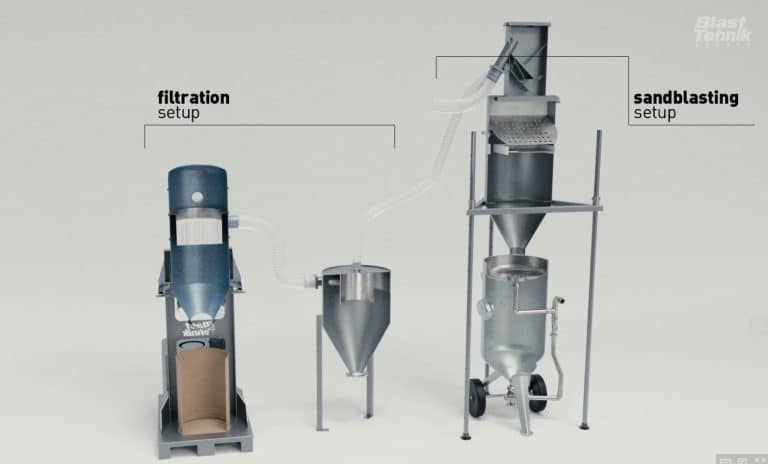

The FILTRATION AND DUST EXTRACTION solution is flexible and fully meets the specific customer requirements for air flow rates up to 30,000 m³/h. The modular design allows for stand-alone installation as well as retrofitting in your existing extraction system. Do you have special requirements such as limited footprint or small height? Owing to a flexible approach that includes modular design, multiple filtering media and configurations, and a wide range of options and accessories, you will get an EXTRACTOR unit for the specific requirements of your plant.

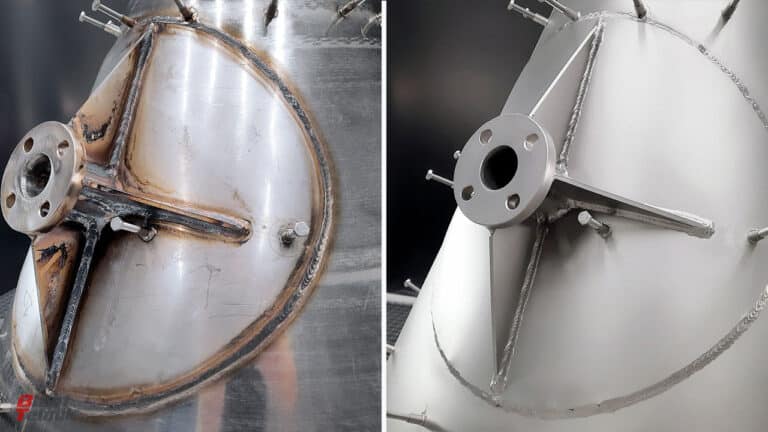

LONGER LIFE AND LOWER MAINTENANCE COSTS

The cartridge filters are thoroughly cleaned with pulses of compressed air (5-7 bar). The proprietary electronic control system PULSE JET activates the electropneumatic valves in the injection columns based on the measured pressure differential between the raw and clean air inside the filter. Optimal program settings for the cleaning procedures ensure a continuous and long-term filter operation even in the most difficult conditions and demanding dust types. The duration of injection of compressed air into any filter type is very short – from 0.016 to 0.1 s. The duration of pauses between the pulses is adjustable between 10 and 250 s. In this way, the service life of the cartridge filters is significantly extended and the maintenance costs are reduced.

WHY CHOOSE THE BLAST TEHNIK FILTRATION SYSTEMS?

- 2 YEAR WARRANTY

- RENT and PURCHASE options available

- CUSTOM turnkey solutions

- in-house SERVICE and CUSTOMER SUPPORT

- spare parts and consumables IN STOCK