Let us guide you through the process of building one of the technologically most advanced robotic blast rooms in the Southeastern Europe. Step-by-step, we present the journey from the concept all the way to commissioning and sophisticated automatic operation.

The automated blast room is designed for automatic blasting of rolls before applying the rubber cover. The rolls can be up to 15 m long, measure 1.6 m in diameter and weigh up to 20 tons.

STEP 1: CONSTRUCTION PIT AND POURING THE FOUNDATIONS

The photo shows a modern robotic automated blast room growing out of the construction pit. The frame structure, L-brackets and rails were assembled before pouring the foundations.

STEP 2: Installation of the scraper system used to transport the blast medium

Installation of the scraper system used to transport the blast medium. The system collects the used blast medium for recycling.

STEP 3: Construction of the steel structure

We installed a precisely fabricated room structure on the prepared foundations as the frame of our technologically advanced blast machine.

STEP 4: WALLS, DOORS AND COMPLEX ENGINEERING

We made the walls from dedicated panels, which guarantee the required tightness of the blast room and meet the most demanding European environmental standards. The interior is wrapped in sound-absorbing rubber covering, which also extends the service life of the blast room. Double-leaf doors were installed in this phase. In the next phase, the doors were automated and connected to the blast room control system. The technology enables proper opening and closing, as well as the required door tightness. Our Engineering made sure that we were prepared for project execution in the best possible way and that there were no major issues in the implementation, despite the technological complexity.

STEP 5: IMPLEMENTATION OF ELECTRONIC AND COMPUTER CONTROL SYSTEMS

Careful and precise engineering and implementation of electronic and computer control system is required to ensure sophisticated automated operation of the robot blast room. This is a core system which allows the booth to be operated by a single operator. Despite the heavy workpieces and large loads, touch-screen control is sufficient for efficient operation of the blast room.

Many sensors in different positions contribute to correct and accurate operation. They also allow the machine to operate safely and prevent accidents during operation. Last and not least, the blasting room is a part of the production process/production line, and as such has to be synchronized and connected to the entire work process in the customer organization.

The automated blast room uses a dedicated IT solution that precisely controls several mechanical operations so that the entire blast process runs as planned.

STEP 6: Relaxed mood throughout the project

Even when things got a bit tense, the boys always knew how to create a good mood and keep a positive attitude throughout the project. There is no doubt that this is one of the main success factors in a technically complex project like this.

STEP 7: Filtration, separation and ventilation system

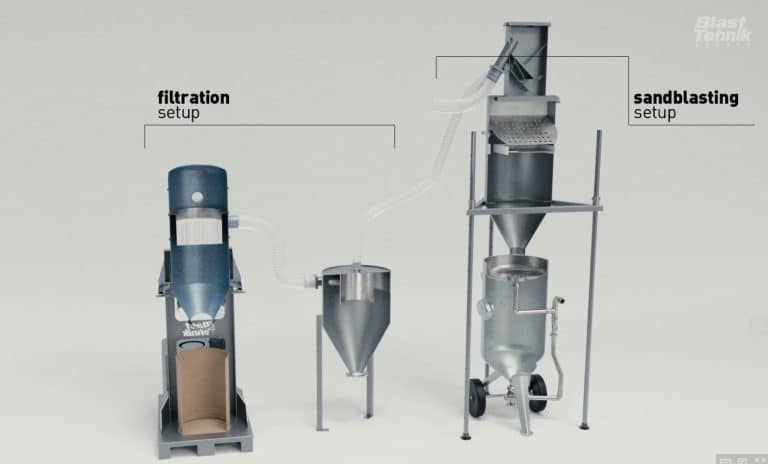

The automated blast room uses a dedicated IT solution that precisely controls several mechanical operations so that the entire blasting process runs as planned.

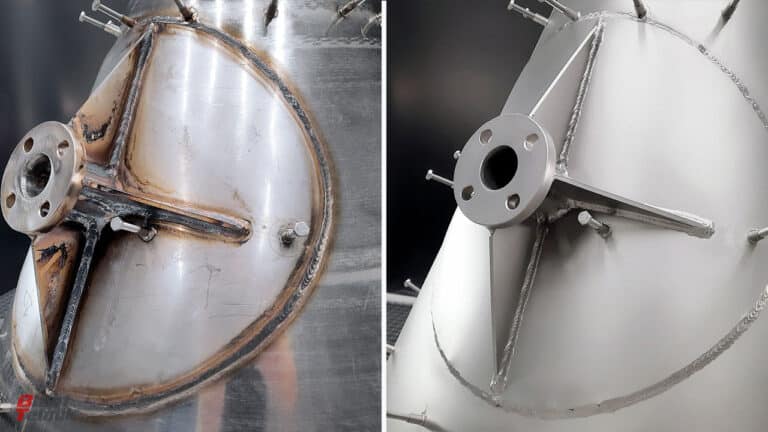

The position of the extremely high-performance fan in the system was selected to ensure the best possible efficiency. The piping system is optimised for the required effectiveness and efficiency. Dedicated filters enable filtration according to the latest European standards. The separation system has proven to be extremely effective in our past projects, so we decided to use it here, too.

STEP 8: Installing the trolley for transporting rolls weighing up to 20 tons

The trolley in combination with the sensors and the control system enables accurate positioning of rolls weighing up to 20 tons. The trolley also allows rotation of the loaded roll in sync with the motion of the blast guns. The technology thus enables extremely precise roll blasting without relying on the operators. The automated blasting line thereby allows error-free operation and consistent repeatability.

STEP 9: Automated blast room - commissioning in manual mode

To ensure minimum downtime of the production process, the room has already been commissioned in this phase, even though some work was still needed to finish the blast room and declare full functionality.

STEP 10: Final commissioning and video showing the operation of the automated blast room

The robotic automated blast booth project was thus finalised as a perfect success. But our journey with the customer has only just begun. The customer will rely on our know-how and experience in the future, as we will continue to monitor the efficiency of the blasting system and implement upgrades and modifications.

We would like to thank all those involved in the project and wish a long service life to one of the technologically most advanced robot blast rooms in the Southeastern Europe.