We are the next in line after the firefighters! When the fire is put out, it’s time for blasting – fire damage recovery!

After a fire, soot and burns remain on wood, brick, concrete or metal. Everything is black and smells of fire!

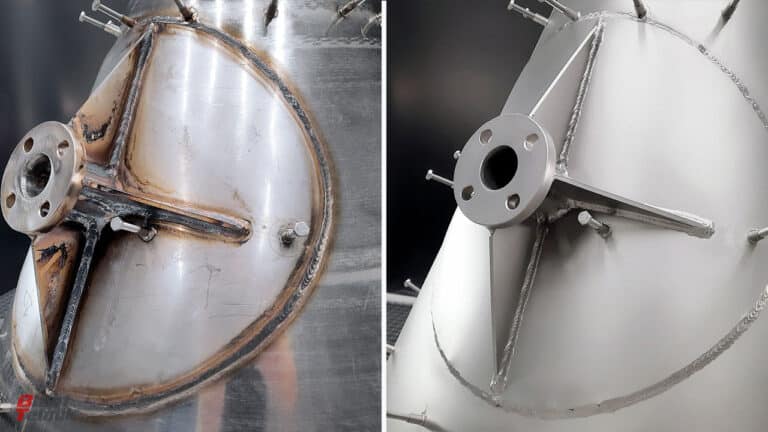

Blast Tehnik – fire damage recovery in the field. Save time and money by doing fire damage restoration in place of ordering new equipment!

Do you want to repair fire damage? CALL US!

After an industrial fire, the production is limited which strongly impacts your business. The damage is already big, but your revenues are also suffering and the jobs are in danger. That is why a rapid and efficient restoration is extremely important!

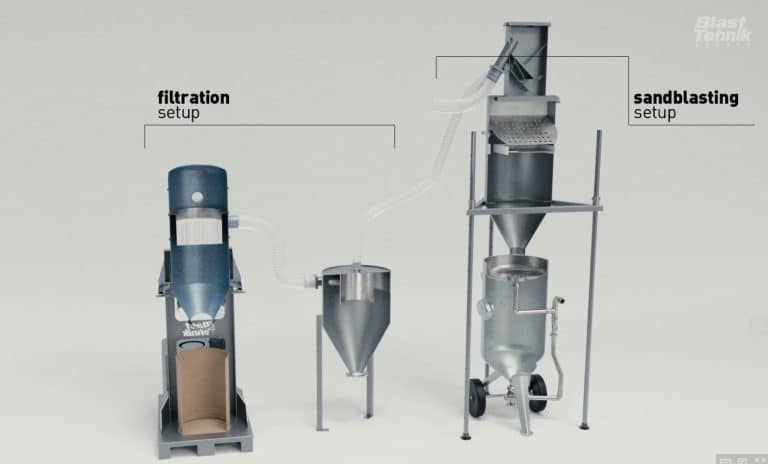

Conventional cleaning procedures are inefficient and time consuming. Blast Tehnik teams are trained to work in the field. We use various blasting techniques to clean materials such as:

- concrete

- stone

- wood

- brick

- metals

We use continuous extraction and filtration to prevent the environment from dust. After finishing our work, the premises are usually available for immediate use, or, as a customer of ours put it: “Blimey, it is just like new!”

The blasting process thoroughly cleans the surfaces and at the same time removes any unpleasant odours. Any sensitive areas (e.g. electrical wiring, ceramics…) are blasted using dry ice. This is a non-abrasive cleaning method that cleans the installations without leaving any secondary residues (dry ice sublimes away after hitting the surface, and only the removed contaminants remain). After the treatment, the surfaces are ready for immediate application of protective paint and/or further use.

Fire damage restoration by Blast Tehnik offers many advantages:

- the process is faster compared to conventional cleaning methods

- less disruption and lower cost

- thorough renovation also allows access to hard-to-reach places

- efficient cleaning/restoration of sensitive/dangerous areas: electrical installations and plumbing

- water- and chemicals-free cleaning

- if required, the surfaces are ready for “decoration” right after the restoration

- unpleasant smell of fire is removed

- environmentally-friendly restoration technique

Call us for more information or to request a quotation – right after the fire:

041 671 002