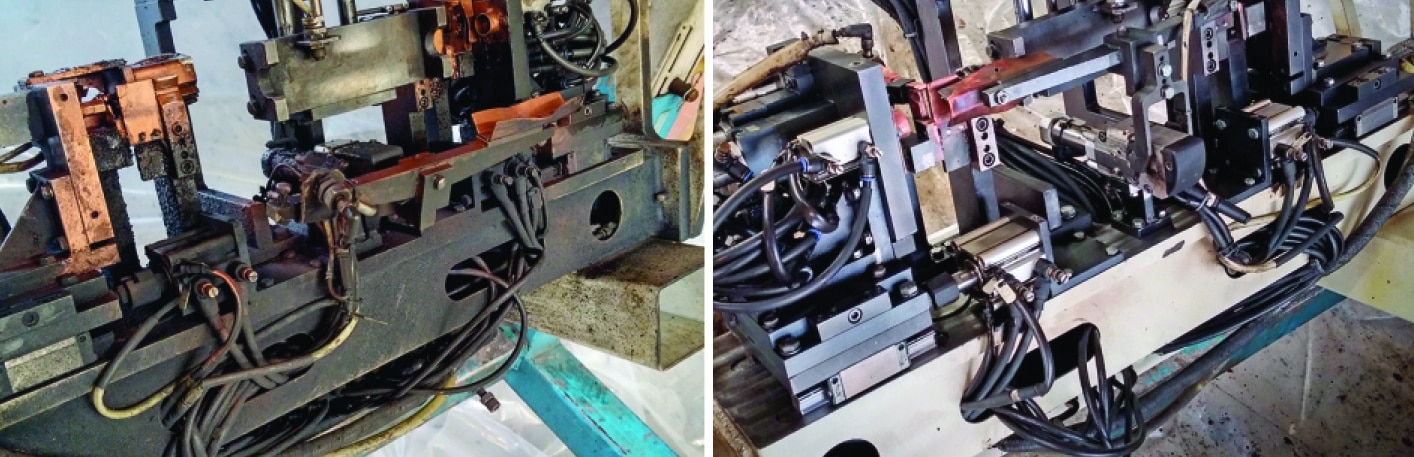

Our solution allows you to immediately test cleaned tools and integrate them into the production process. This means less downtime, always flawless tools and the highest quality of your products.

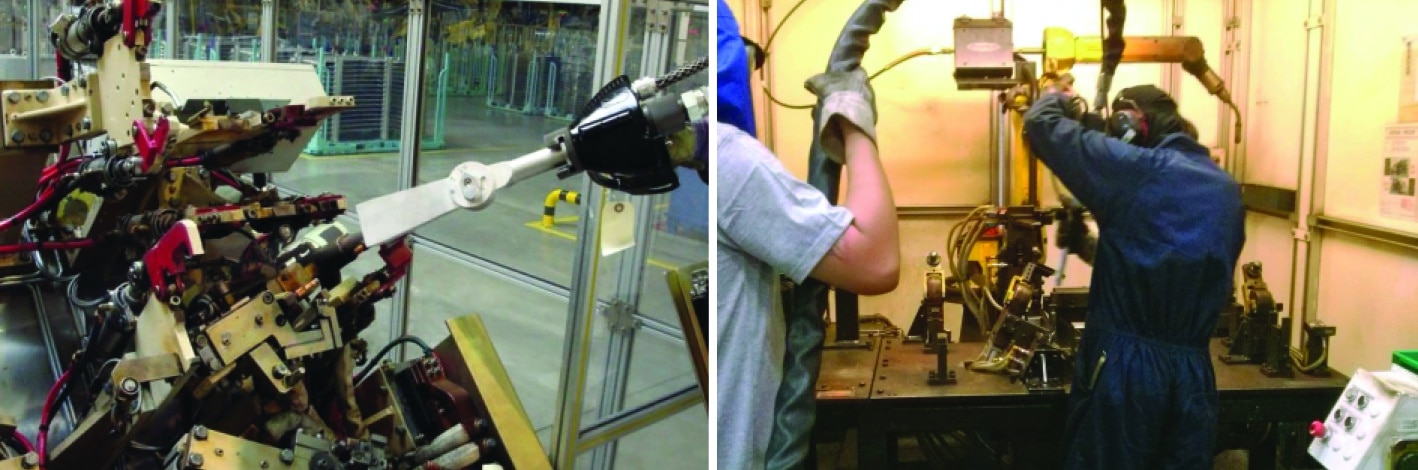

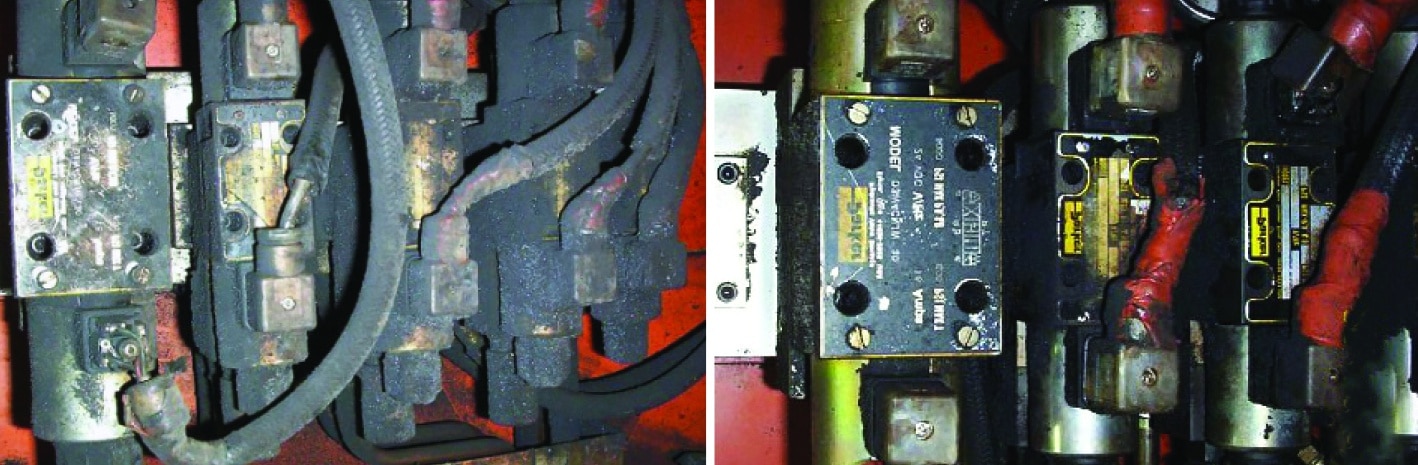

Cleaning of robust welding arms, tools, tables and clamps - on site, without disassembly and without water and cleaners. Longer device life and lower maintenance costs.

We remove epoxies, sprays, scale and heat-resistant pastes (copper, etc.) in a completely safe and effective way, which enables the proper functioning of contact, fastening and moving segments.

After cleaning, immediate use in production is possible, without negative effects on operation or. functions.

Contact us and we will be happy to answer your question.

Sign up for our news and stay ahead of the competition with the latest information on surface treatment.

From the production of the most demanding sandblasting machines to the implementation of top-quality sandblasting services.